In dense cities and bustling neighborhoods, a taco truck isn’t just food on wheels—it’s a portable, adaptable business that speaks to busy commuters, outdoor enthusiasts, and entrepreneurial souls. The appeal is simple: great, craveable tacos served fast, in convenient locations, with a brand people recognize and return to. The challenge is turning that appeal into a reliable operation that fits tight street permits, limited space, and fluctuating foot traffic. This guide takes you through three chapters that align your dream with practical steps you can implement today.

Chapter 1 lays the groundwork: clarifying your concept, identifying your primary audience (urban commuters, outdoor enthusiasts, small business owners and freelancers who value quick, delicious meals on the go), and building a solid business strategy. You’ll map startup costs, pricing, and revenue expectations, so the plan doesn’t stay on paper but becomes a living document you revisit weekly.

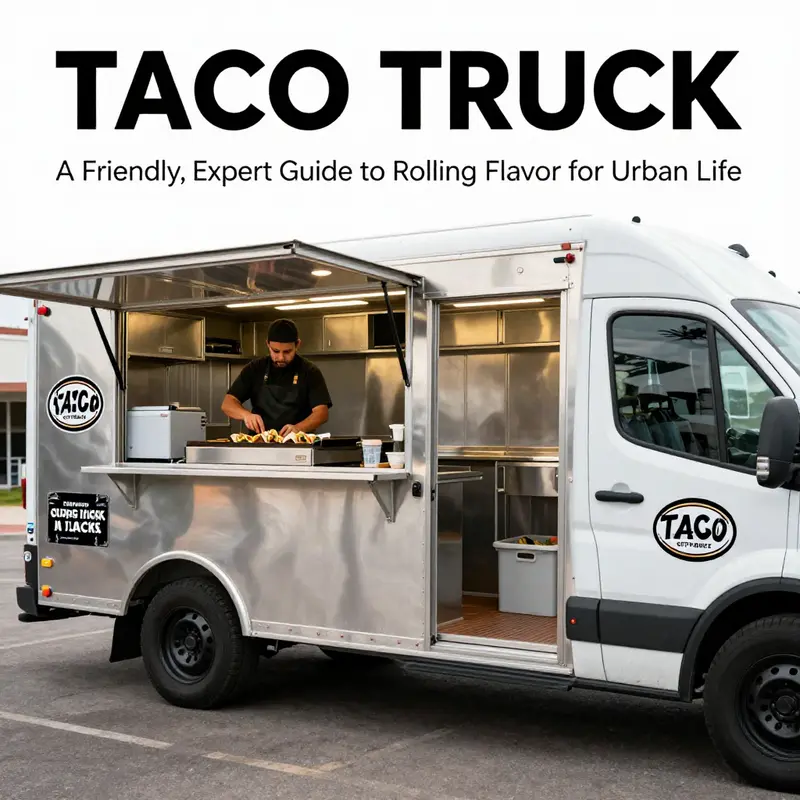

Chapter 2 dives into the heart of the truck itself: vehicle selection, kitchen design, and equipment. We’ll translate your strategy into a kitchen that works in a compact mobile footprint—efficient layouts, essential gear, sanitation, ventilation, and branding that travels with you. The goal is a smooth cook-to-order flow that keeps lines short and quality high, even during peak hours.

Chapter 3 covers permits, launch, marketing, and growth. You’ll learn how to navigate local health and business regulations, choose high-traffic launch locations, and build a following through smart marketing and partnerships. This chapter also explores scalable steps—what to upgrade first, how to expand locations, and when to add delivery or catering services—so your taco truck remains nimble as demand grows.

Together, these chapters create a holistic roadmap: start with a purposeful plan, design a kitchen that fits your reality, and execute a compliant, scalable launch that connects with urban audiences. By the end, you’ll see how every decision—from menu simplicity to location strategy and branding—supports a single outcome: dependable daily sales and a recognizable, beloved taco brand on wheels.

Blueprint for Success: Planning, Positioning, and Financing Your Taco Truck Venture

Launching a taco truck starts with a plan that ties a clear concept to realistic operations and solid finances. A well-crafted strategy turns a love of food into a sustainable business by aligning what you sell, where you sell it, and how you will reach and keep customers. This chapter walks through the essential planning elements—concept and brand, market and location, legal and regulatory priorities, cost and financing, sourcing and equipment decisions, and marketing foundations—so you can move from idea to action with confidence.

Begin with a focused concept. A taco truck cannot be everything to everyone. Choose a concise idea that guides menu choices, equipment needs, and brand messaging. Whether you center on classic street tacos, regional specialties, a fusion approach, or plant-based tacos, your concept should answer two questions: what makes your food distinct, and who will buy it. Narrowing your focus helps keep the back-of-house efficient and your food consistent. It also creates the basis of your unique value proposition: the reason customers seek you out rather than another truck.

Define your target customer with real detail. Picture the weekday lunch crowd, evening festival-goers, late-night bar patrons, or families at local markets. Consider demographics, schedules, and spending habits. Office workers may value speed and predictable pricing. Students often prefer bold flavors at lower price points. Event attendees will pay for convenience and novelty. Use this profile to shape portion sizes, pricing tiers, operating hours, and even the truck’s visual identity.

Translate concept and customer into a simple, signature menu. Success comes from a compact offering executed extremely well. Limit core taco varieties to three to five signatures, each built around techniques that scale: grilled meats, slow-cooked braises, marinated vegetables, and one reliable protein swap for dietary needs. Add two or three sides and a couple of beverages to increase checks without complicating prep. Keep recipes consistent and standardized so a small team can reproduce them quickly. Standardization reduces waste, improves speed, and makes training faster.

Location strategy is the operational backbone. Mobile food thrives on visibility and foot traffic. Map high-opportunity zones near offices, campuses, transit hubs, parks, and event venues. But success is not only about the number of potential customers; it is also about the predictability of that traffic and the legal ability to serve there. Scouting should combine physical observation and regulatory research. Spend time at prospective spots during planned service hours. Note nearby competitors, where customers congregate, and how long people linger. Build a routine route with trusted high-traffic days and variability for special events.

Understand local rules before you invest. Municipal regulations shape where and when you can park, what permits you must hold, and which health standards apply. Early research avoids costly redesigns and delays. Identify the mobile food vendor license, health department requirements, vendor parking permits, and any special district restrictions. Determine if you must operate from licensed commissaries or meet wastewater disposal rules. Factor in food handling certifications for you and your staff, and secure appropriate liability insurance. Treat compliance as a non-negotiable part of your launch timeline rather than a last-minute box to check.

Estimate startup costs with conservatism. A credible projection includes vehicle acquisition or lease, kitchen outfitting, permits and licenses, initial inventory, branding, point-of-sale systems, and working capital for the first months. Typical ranges vary widely based on vehicle condition and equipment choices. Prepare line-items for unexpected expenses like emergency repairs or extended permit timelines. Build a buffer of three to six months of operating capital to cover payroll, fuel, maintenance, and inventory while you build a customer base.

Choose your vehicle with both immediate needs and long-term flexibility in mind. Many operators select a full-sized truck, a converted van, or a towable trailer. Each option has trade-offs in initial cost, interior space, and maneuverability. Prioritize kitchen layout that minimizes steps and cross-traffic: work zones for prep, cooking, plating, and storage should flow in a logical sequence. Fit the vehicle with commercial-grade surfaces and easy-to-clean materials. Install proper ventilation and fire suppression where required. When sourcing equipment, weigh up initial price against expected lifespan and serviceability. High-quality griddles and refrigeration cut long-term costs by reducing downtime and waste. For guidance on selecting equipment that matches operational demands, consider a resource on choosing food truck equipment wisely.

Decide whether to buy locally or source components internationally. Both routes can produce reliable builds, but they demand different approaches. Domestic suppliers may offer easier regulatory alignment and faster support. Overseas manufacturers can provide cost advantages and rapid production capacity, but they require careful vetting for quality standards, shipping logistics, and after-sales service. If you explore international options, shortlist vendors with verifiable references and clear documentation of compliance with your jurisdiction’s safety standards. Clarify lead times and warranty terms to avoid surprises.

Create a financial model that clarifies break-even dynamics. Build conservative revenue projections based on daily check averages, number of service hours, and expected customer throughput. Itemize fixed costs—vehicle payments or lease, insurance, storage or commissary fees—and variable costs—food, packaging, labor, fuel. Run scenarios for low, medium, and high sales weeks to understand cash flow sensitivity. The model will guide pricing and staffing choices and serve as a communication tool for potential lenders or partners.

Plan for permits and health compliance early. Health departments typically inspect mobile kitchens for proper food storage, temperature control, handwashing facilities, and sanitation practices. Have detailed kitchen schematics ready and choose materials that meet health code expectations. If your city requires a commissary kitchen for storage or prep, make arrangements and budget for those fees. Treat training in food safety as part of your operating plan; it reduces risk and builds customer trust.

Assemble supplier relationships that reinforce consistency. Reliable vendors shorten lead times and minimize menu interruptions. Source primary suppliers for proteins, tortillas, produce, and staple dry goods. Establish backup suppliers for critical items to hedge against shortages. Negotiate terms that match your cash flow; smaller operators benefit from weekly or biweekly deliveries to limit working capital tied up in inventory. Prioritize quality for core ingredients that define your tacos; a superior tortilla or salsa can elevate even simple fillings.

Design branding that reinforces your concept and makes the truck instantly recognizable. Your name, logo, and truck wrap should convey the food’s personality and set expectations for speed, price, and flavor. Keep the visual identity legible from a distance; bold colors and simple typography work best in street settings. Extend branding to packaging and staff uniforms for a cohesive experience. Social media images should match the visual tone of the truck, reinforcing recognition across channels.

Train your team for speed and hospitality. Efficient service is the product of practiced workflows and clear roles. Drill assembly sequences until they become muscle memory. Use mise en place to reduce decision points during service. Teach staff how to manage lines, upsell add-ons, and handle peak-volume communication. Customer interactions are short, so train staff to be friendly, clear, and fast. Staff that can flip orders quickly while maintaining quality directly increases sales per hour.

Create a simple but effective marketing plan. Social media offers the highest return for most taco trucks. Post reliable location updates, high-quality food photos, and behind-the-scenes content to humanize the brand. Use stories and short clips to show daily specials and prep. Encourage followers to tag the truck and share photos; user-generated content functions as social proof and an authentic extension of your reach. Consider a basic loyalty mechanism—digital punch cards or a small discount after several visits—to incentivize repeat business. Participate in local events and collaborate with other vendors or nearby businesses to broaden exposure.

Plan logistics for operations and growth. Track daily sales, peak hours, top-selling items, and inventory turns. Use this data to refine menu offerings and staffing. Maintain a maintenance schedule for the vehicle and equipment; small repairs prevent large breakdowns. When growth is viable, consider extended hours, catering, or third-party delivery integration to reach customers who cannot come to your truck. Each expansion should be tested against the financial model before committing capital.

Mitigate risks with insurance, permits, and contingency planning. Liability insurance protects against customer incidents. Equipment insurance and roadside assistance reduce the impact of vehicle failures. Keep digital and physical copies of permits and certifications on board and accessible. Maintain a cash buffer and a plan for temporary closures, whether due to weather, equipment failure, or permit issues. A resilient operation adapts quickly and communicates clearly with its customer base when service changes occur.

Finally, remember that planning is iterative. Use early weeks of operation as structured learning. Gather feedback, analyze sales, and adapt the menu, schedule, and locations accordingly. The most successful taco trucks blend culinary consistency with operational agility. By developing a strong concept, securing the right permits, building reliable supplier relationships, and modeling conservative finances, you create the conditions for sustainable growth.

For a practical guide to sourcing trailer manufacturers and navigating supplier comparisons, consult this industry guide: https://www.shopify.com/blog/taco-truck-trailer-supplier-guide

For further reading on selecting truck equipment tailored to efficient operations, see this resource on choosing food truck equipment wisely.

On Wheels and in Motion: Designing the Vehicle, Kitchen Layout, and Equipment Backbone of a Taco Truck

The road is the stage for a taco truck, but only if the vehicle, the kitchen layout, and the equipment behind the window work in concert. This chapter treats these three strands as a single, living system: the chassis that carries the dream, the interior that makes it possible to cook with consistency, and the gear that translates a menu into rapid, safe service. A taco truck isn’t just a mobile restaurant; it is a compact, highly engineered workspace where every decision about space, flow, and tools cascades into flavor, speed, and profitability. When you choose a vehicle, design the kitchen around it, and equip it with modules that can handle peak demand without breaking down, you set yourself up for reliability, repeatable quality, and the kind of service that turns first-time customers into regulars. The narrative here follows that logic, weaving practical guidance with the realities of real-world operations so the path from concept to curbside service feels less like a gamble and more like a deliberate construction project grounded in core necessities and scalable ambitions.

The decision about which vehicle to buy is the most consequential step in this chapter of the journey. For a taco operation that wants to combine speed, capacity, and menu breadth, a large, rectangular food truck is often the most practical starting point. Its interior offers generous layout space, which translates into distinct stations for grilling, sautéing, prep, and assembly. The footprint matters because it dictates how many cooks you can staff, how many menu items you can reliably prepare during a rush, and how easily you can maintain clean lines between raw ingredients, cooking, and finished products. In a kitchen-on-wheels, space efficiency isn’t a luxury; it is a requirement for staying within health codes, controlling cross-contamination risks, and keeping the operation moving during the lunch crush or a bustling festival.

A large, rectangular configuration is notable for its flexibility. It can accommodate multiple cooking stations side by side, allowing a grill or griddle to anchor the hot line while a fryer, if your concept requires it, sits a comfortable distance away with dedicated ventilation. Behind the scenes, a well-planned interior layout sets up a logical sequence: cold storage to hot service to assembly, with a scrub and handwashing zone that remains accessible but discreet. The interior, when finished with durable, easy-to-clean materials such as stainless steel panels, non-slip flooring, and water-resistant joinery, becomes a durable canvas that withstands the daily churn of high-volume service. This is not just about keeping up; it is about staying ahead of the inevitable twists of a busy service window—spills, grease, rushes, and the unpredictable rhythm of a crowd that can swing from quick bites to extended orders in minutes.

If your concept centers on signature dishes that revolve around “build-your-own” or multi-taco offers, the interior must allow rapid assembly without bottlenecks. The work steps—grill or sear, transport to prep, knife work, topping deployment, salsa handling, wrap and bag—need a fluid chain with minimal backtracking. In practice, that means a zoning strategy that places the prep sink and cold storage within arm’s reach of the knife station, a ventilation hood that adequately captures cooking exhaust without overpowering the dining area, and a dish line or packaging area that doubles as the final assembly point. These decisions ripple outward into daily operations: they influence how you train staff, how you schedule shifts, and how you stage peak-time readiness. A well-drilled workflow, in other words, becomes your most valuable asset because it converts raw equipment into reliable service.

The vehicle choice doesn’t exist in a vacuum. Alternative configurations deserve careful consideration if your business model or budget points you toward different kinds of mobile platforms. A cargo trailer can be a viable path when you want strong climate control and a modular interior that can be reconfigured for frequent menu changes or seasonal offerings. Trailers offer robust, climate-controlled storage and can be outfitted with multi-station prep spaces that still feel like a compact kitchen when you roll into a permit check or a festival gate. They are particularly appealing for operators who want to separate a heavy cooking system from a front-facing service window while still delivering a seamless dining experience. A canteen-style unit, designed for rugged field operations or bulk meal service, can be a source of design inspiration for durability and modularity. If you are catering to construction sites, disaster relief zones, or large-scale events, the canteen’s emphasis on robust interiors, modular layouts, and integrated utility systems can spark ideas for how to structure a taco truck that endures harsh conditions while remaining nimble enough to deliver high-quality meals.

The central idea is clear: align your vehicle’s form with the menu, then align the kitchen with the flow of people. If your plan involves quick, high-volume service with a broad menu that includes grilled meats, fresh salsas, and a handful of sides, you’ll want space for a real grill or griddle, a capable refrigeration system, and a prep area that can handle multiple cooks without stepping on each other’s toes. The material choices then come into play: stainless steel for walls and counters reduces corrosion and makes cleanup predictable; durable flooring minimizes wear; and stain-resistant, sealed surfaces reduce the risk of grease penetration and staining. The environment must invite efficient, sanitary work while projecting a clean, professional image to customers waiting at the window. In other words, the vehicle and its kitchen are not merely tools; they are the physical translation of your brand promise—a promise that you can prepare, plate, and serve delicious tacos consistently, no matter how long the line becomes.

Branding is often considered separately from the kitchen’s practicalities, yet it belongs here. The vehicle’s exterior and the interior layout should speak the same language as your menu and your customer experience. A cohesive look helps travelers and potential repeat patrons recognize your truck, understand what to expect, and remember you when they crave a particular flavor profile. Branding work should begin with a clear articulation of how your concept will be perceived at the curb, in a festival lineup, or at a pop-up market. The interior design, though mostly functional, should echo that brand language through color, texture, and the quality of finish. A well-branded kitchen communicates confidence to staff, suppliers, and customers alike. It signals that this operation is serious about consistency, cleanliness, and the craft of Mexican-inspired street food.

With the vehicle selected and the kitchen layout sketched, the equipment list becomes the practical grammar that translates concept into action. At a minimum, you’ll need a capable cooking platform—a commercial-grade stove and a griddle that can handle searing carne, sautéing vegetables, and finishing toppings across a steady stream of orders. A ventilation system that moves smoke and heat efficiently is essential for safety and comfort, and it should be matched to the cooking load planned for the truck. Refrigeration stands at the core of menu integrity: you’ll be storing raw ingredients, prepped toppings, and finished products, so you need reliable reach-in or under-counter units with stable temperatures and adequate space for organization. A dedicated prep sink, a handwashing sink, and a dedicated utility sink for cleaning and sanitizing are not optional luxuries in a mobile kitchen; they are requirements that ensure compliance with health regulations and a clean workflow. Alongside these, you’ll need proper storage solutions—ventilated shelves, modular drawers, and pull-out bins that keep utensils, packaging, and ingredients in reach without crowding the work surface.

In many taco concepts, the equipment set is the engine that makes the menu sing. If you chase a lean startup path, you can begin with a focused suite: a large griddle for meats and vegetables, a compact stove or additional burner for simmered salsas or beans, a sink cluster with a dedicated prep sink and a hand sink, a robust reach-in refrigerator, and a small freezer for perishables. If your menu sprawls toward fried items or multi-temperature toppings, you may add a fryer and a second refrigeration zone to keep ingredients properly chilled during assembly. The placement of these items matters just as much as the items themselves. A common, effective strategy is to place cold storage toward the back of the truck, with prep surfaces and the hand sink in the middle, then the hot line near the front for rapid transfer to the service window. This arrangement supports a smooth theatrical rhythm as cooks move between raw prep, cooking, and finishing—the choreography of service becomes the show, and the equipment is the script.

Choosing equipment wisely is a decision that benefits from a measured approach. It is tempting to load up on features and gadgets, but a taco truck must stay nimble and affordable. Start by cataloging the menu’s core items and the steps required to produce them at high speed. Then map out the equipment interactions: which devices share power resources, which need dedicated ventilation, which require cold storage, and how close the prep space must be to the cooking line. A well-structured plan reduces redundant or underutilized gear and minimizes the risk of mismatched capacity during peak hours. It also makes future upgrades more straightforward because the base configuration is already modular and scalable. For operators who want to optimize equipment choices while preserving flexibility, a practical principle holds: prioritize reliability, ease of cleaning, and the ability to perform routine maintenance without disrupting service. A durable, well-organized truck reduces both downtime and waste, helping you keep margins healthy even when demand spikes.

Even with a strong vehicle and an efficient layout, training and maintenance are the invisible gears that keep the machine turning. A kitchen designed with clear zones and logical flows makes it easier to train staff to follow the same patterns during every shift. You can develop simple, repeatable prep sequences that keep toppings consistent from day one, and you can establish a dry-run routine to practice assembly in rush conditions. The goal is to turn the kitchen into muscle memory for the team, where the best practice becomes instinctive. Maintenance schedules should be built into the routine, not tacked on as an afterthought. Regular cleaning, calibration of refrigeration temperatures, testing of the ventilation system, and inspection of gaskets and seals around every piece of equipment are non-negotiable habits for mobile kitchens that service demanding environments. The vehicle’s condition, much like a car’s, will determine reliability on the long road. A dented panel, a lagging hood latch, or a misaligned shelving unit can throw a wrench into a service window; proactive, disciplined maintenance prevents those disruptions.

From a strategic point of view, aligning vehicle type, kitchen design, and equipment with the target market is essential. If you aim to serve at offices and late-afternoon campuses where lunch turnover is rapid, you may emphasize speed, compactness, and a lean menu that can be served within minutes. In that scenario, the interior might favor a high-output grill, compact refrigeration, and a simple yet sturdy service window that keeps the line moving. If your heart is drawn to events and festivals where you can experiment with flavors and offer a broader range, a larger vehicle with a more expansive kitchen may be warranted. You’ll need a plan for power, water, and waste that scales with the event footprint, and you’ll want to think about how to protect your equipment during transport and while parked in high-traffic areas. Each choice carries a cascade of implications: permit considerations, insurance requirements, and the logistics of moving a larger unit into and out of venues. These realities are not obstacles; they are design constraints that sharpen your decisions and force you to be intentional about every square inch of space.

As you approach the practical phase of outfitting, the balance between ambition and reality becomes the guiding thread. The vehicle’s capacity must meet the menu’s ambitions without inviting waste, and the kitchen’s layout should be robust enough to handle busy days while remaining adaptable to evolving offerings. The equipment list should be curated with a clear sense of what is essential today and what can be added as the brand grows. For many operators, the best path is a staged build: begin with a solid core—grill or griddle, a reliable cold storage system, a couple of prep stations, a handwashing sink, and a basic ventilation setup—then phase in additional gear as demand justifies it. This method preserves cash flow, reduces risk, and keeps the truck nimble enough to pivot toward new opportunities, whether that means a different market, a seasonal menu, or a shift in customer demographics.

The practical dimension of this chapter—vehicle selection, kitchen design, and equipment—also demands respect for regulations and safety without letting compliance overshadow creativity. Local health departments, fire marshals, and zoning authorities will scrutinize your setup, but their concerns are not an adversary; they are a framework that ensures you serve delicious food in a safe, sustainable way. The right vehicle and a thoughtfully planned interior create not just a kitchen on wheels, but a disciplined space where quality is forgone for any excuse, and where the customer experience from first glance to the last bite reflects the care you invested in design, sourcing, and training. A taco truck built on this philosophy is more than a business; it is a platform for flavors to travel with integrity, to arrive hot, fragrant, and ready to delight a diverse audience.

To deepen the practical understanding of vehicle types, kitchen layouts, and equipment recommendations using industry benchmarks, you can consult comprehensive guidance from established industry resources. For instance, a widely cited reference discusses vehicle types and their uses, including how interior layouts support different culinary approaches, what standards govern kitchen design on wheels, and how equipment selection feeds into throughput and service quality. Choose food truck equipment wisely can serve as a useful internal touchstone as you translate these principles into your own build plan. This step is about translating knowledge into a concrete, actionable blueprint you can hand to a designer, a fabricator, and your team as you move from dream to street.

As you finalize the design, remember that the vehicle, the kitchen layout, and the equipment are inseparable components of a single system. The road demands reliability, not just ambition. The kitchen demands cleanliness and efficiency, not just novelty. The equipment demands thoughtful placement and robust performance, not just glossy capability. When these pieces align, your taco truck becomes a mobile microcosm of a well-run kitchen, where the aromas of roasted peppers and sizzling meat rise in a controlled, predictable rhythm, and where guests experience a sense of certainty—certainty that what lands in their hands is prepared with care, plated with consistency, and served with warmth. The journey from concept to curbside becomes a confident stride rather than a leap of faith, and the business grows not by luck, but by design.

External resources can offer broader perspectives on vehicle types, including considerations for size, climate, and long-term durability. For a more expansive, standards-based exploration of vehicle types and kitchen design principles, see the National Food Truck Association’s guidance on vehicle types and their uses. This resource helps anchor your planning in industry benchmarks and practical case studies, ensuring your build anticipates common pitfalls and embraces proven configurations. https://www.nationalfoodtruckassociation.org/vehicle-types

Chapter 3: On the Road to Taco Triumph — Navigating Permits, Launch, Brand, and Growth for a Winning Taco Truck

The journey from a spicy idea to a fully wheeled, bustling taco truck begins long before the first sizzle of a griddle. It starts with clarity about what you want to serve, where you want to serve it, and the practical lines of discipline that separate a dream from a dependable, legal, and profitable operation. This chapter guides you through the intertwined paths of permits, vehicle readiness, safety, and the kind of launch that creates momentum rather than a one-night stand with a crowd. In the end, a taco truck is more than a menu on wheels; it is a carefully choreographed system that must respect regulations, protect guests, and still feel effortless to the people serving and the people enjoying the food.

Permits and licenses form the backbone of legitimacy, but they are not a box to check and forget. They are the framework that legitimizes your concept and protects your customers, your crew, and your business from the unpredictable dynamics of street service. The first decision—how you structure your business—sets the legal tone for the rest. You might choose a sole proprietor path to keep things simple, or you may elect an LLC or another structure to shield personal assets and to facilitate growth. An Employer Identification Number helps you separate personal finances from business operations, and it lays the groundwork for tax reporting, payroll if you hire, and more formal vendor relationships. Beyond that, you will seek a health department permit tailored to mobile food service, then arrange a vehicle inspection that confirms your kitchen meets handling, temperature control, and sanitation standards. Fire safety typically requires vented hoods, extinguishers, and a plan for incident response. You will also navigate insurance—general liability, commercial auto coverage, and perhaps product liability—so that a misstep by a customer does not derail the entire enterprise. Location permissions and zoning clearances complicate the calendar, because cities often expect a set of designated vending zones or event permits, and street-facing signage may demand separate approvals. It is not unusual for a 4- to 12-week window to unfold from first inquiry to the first service, and the range rests on jurisdictional appetite, completeness of submissions, and how quickly you organize required documents.

With the legal skeleton in place, vehicle and equipment readiness takes center stage. A taco truck requires a kitchen that can stand up to the pace of a lunch rush and the wear of daily operation. Your vehicle choice—whether a purpose-built mobile kitchen, a converted van, or a trailer—should align with your route strategy, the space needed for a high-throughput assembly line, and the need for reliable cold storage, hot holding, and a sanitation station that makes legal compliance practical every shift. Interior layout matters as much as the exterior aesthetic. Think through the flow from receiving to prep to cooking to service, and you will reduce bottlenecks and keep the line moving. Essential equipment includes a commercial-grade stove or griddle, a surface for masa handling and toppings, a reliable refrigeration unit, a sink setup that supports three-compartment washing and handwashing, and storage that keeps ingredients organized and safe from cross-contamination. Ventilation is not decorative; it is a lifeline that keeps the workspace within healthy limits and protects staff from exhaust buildup. Durable, easy-to-clean materials—stainless steel surfaces, non-slip flooring, and sealed seams—are investments that pay for themselves through long service life and easier maintenance. Many operators also rely on a commissary or shared kitchen space to satisfy sanitation code requirements for toilets, wash stations, and a place to store ingredients out of the vehicle. If you plan to rely on a generator, ensure your electrical load planning accounts for peak cooking times and the quiet hours that may govern certain districts.

The health, safety, and food-safety practices are not separate from the financial plan but are inseparable from long-term profitability. A HACCP-style approach—mapping critical control points such as receiving, storage temperatures, cooking temperatures, hot and cold holding, cooling, and sanitation—provides a reliable scaffold for daily practice. Temperature control is especially crucial: cold items should be held at or below 40 degrees Fahrenheit, hot items above 140 degrees, and cooling must follow safe timelines to prevent bacterial growth. Documentation of temperatures, cleaning schedules, and sanitizer concentrations is not merely bureaucratic; it is a live record that protects you, your staff, and your guests during a health inspection and in everyday operations. Training staff in basic food safety, personal hygiene, glove and hair restraints, and strict handwashing ensures consistent quality and minimizes risk. Allergen management must be embedded in recipes and kitchen routines, with clear labeling and, where possible, dedicated prep spaces to minimize cross-contact. Pest control and routine maintenance are ongoing commitments—an outward-facing business must keep exterior spaces clean, seal entry points, and schedule regular service to avoid disruptions.

As you prepare for launch, the menu becomes a strategic instrument rather than a mere list of offerings. A small, high-throughput set of signature tacos—two or three protein options, a couple of toppings, and a few side items—lets you maintain consistency while delivering rapid service. Standardized recipes, measured portions, and predictable plate presentation protect margins even during busy periods. Pricing must reflect food costs, labor, and overhead, but you also want to offer value to first-time customers while maintaining a sustainable bottom line. The route plan is the second strategic lever. Identify high-traffic locations that align with your brand—office clusters during midday, parks and community spaces in the evenings, events, and markets on weekends. Establish a consistent schedule so regular customers can find you, while also building a flexible plan to pivot toward events when opportunities arise. A well-chosen point-of-sale system should cope with busy food-service demands and offer simple tax reporting for sales in various locales. Supplier relationships matter: reliable produce, meat, tortillas, and sauces with predictable delivery schedules prevent stockouts during peak hours. A soft launch—perhaps at a lower-stakes location or a small event—allows you to test kitchen flow, validate the menu, and calibrate pricing based on real customer feedback. The soft launch is as much about learning as it is about feeding people; the knowledge gained forms the map you will follow for future expansions.

Branding and marketing, while marketing in the common sense, should be thought of as the DNA of your truck. Your truck’s skin, the wrap, the logo, and menu boards are your first handshake with a passerby. A compelling visual identity helps customers recognize and remember you, but it must also translate into practical tools: well-lit, clear menu boards that can be read from a distance, and a consistent voice across social media that feels human and local. Digital presence becomes the day-to-day engine for location updates and promotions. A simple website or landing page with an updated schedule, menu, and contact information supports both organic discovery and emergency planning if you need to adjust locations due to weather or events. Active social media feeds—especially visually driven platforms—offer a direct line to recent customers and curious newcomers. Show the food in motion: a tortilla crisping on a hot surface, a drizzle of salsa, the steam from a freshly filled taco. Beyond the visuals, consider a loyalty approach that acknowledges repeat customers without burdening you with overly complex systems. Local partnerships amplify reach: offices that want a reliable lunch option, campuses that welcome late-night bites, or events that feature multiple food vendors for a curated experience. Participating in fairs, markets, and street festivals creates social proof and new customer data that can feed a simple email or text-based outreach for future drops.

Growth, of course, is a natural horizon once you have an operational rhythm that works. Growth is not about rushing into a second truck before you can afford lunch; it is about repeating success, maintaining quality, and expanding thoughtfully. A scalable model often begins with standardized SOPs that apply across a fleet and a team trained to execute them with precision. Cross-training staff allows you to cover peak times and vacation periods, while centralized inventory management leverages volume for better supplier terms. The question of growth frequently centers on whether you scale within a similar market, meaning another truck with a comparable menu in a nearby neighborhood, or whether you branch into a complementary concept—perhaps a beverage-focused unit or a different regional style that pairs well with your original concept. Catering and private events become natural revenue streams that complement regular routes, enabling you to test new dishes on a controlled audience while expanding brand visibility. Ghost kitchen or commissary arrangements offer a delivery-focused channel that can run alongside the mobile unit, protecting margins when you need to offset fixed costs with a broader reach. The common thread in any growth plan is the discipline to preserve quality, maintain regulatory compliance, and keep the guest experience consistent across all venues.

Key performance indicators, or KPIs, help translate every decision into a business signal. The metrics you watch should cover revenue and sales dynamics—daily totals, average ticket, and items sold per hour—along with cost control measures such as food cost percentage and labor as a share of sales. Operational efficiency metrics, including order accuracy and speed of service, reveal where the process is strong and where it needs refinement. Compliance and quality measurements, like inspection scores and sanitizer validation, anchor the safety culture that underpins customer trust. When growth becomes a real objective, you track customer lifetime value, repeat visit rates, and the cost of acquiring new customers through marketing initiatives. A disciplined 90-day action plan can anchor your early momentum. In Weeks 1 and 2, focus on securing permits, confirming commissary arrangements, and locking branding foundations. Weeks 3 and 4 bring equipment installation and system testing, followed by supplier onboarding. Weeks 5 through 8 should include a soft launch, a debrief with your team, and a refined operations plan. Weeks 9 through 12 mark the official rollout: a consistent location schedule, a steady social media cadence, and a few early promotional pushes to generate the critical mass of daily customers. And beyond the initial three months, the real test is whether you can translate that momentum into expanded locations, more reliable supply chains, and a scalable organizational model that can ferry your brand across neighborhoods without compromising the essence of what makes your tacos compelling.

To keep this journey grounded in practical realities, consider a resource that highlights sustainable practices specifically for mobile food operations. It offers actionable ideas around waste management, energy efficiency, and responsible sourcing that align with the ethos of a well-run truck without turning sustainability into a separate project. You can read more here: Sustainable practices for mobile food trucks. As you contemplate the structural choices and the daily routines, remember that the road you choose is not only the route for your truck but the pathway for your business culture: a culture of safety, reliability, hospitality, and relentless improvement. When guests walk away with a memorable bite and a positive impression of their experience, the truck has already earned its place in the community. The final layer of guidance is outward-facing and practical. For broader regulatory guidance on how to navigate permits, licenses, and formal business steps, you can consult official resources such as the U.S. Small Business Administration’s food truck guide. It helps you align timelines, costs, and compliance with established best practices, reducing the guesswork that can turn a promising concept into a fragile venture. You’ll find this starting point and many related templates at https://www.sba.gov/business-guide/plan-your-business/start-food-truck-business. This chapter has traced the throughline from permit to launch, brand, and growth; the actual execution will hinge on your local context, your personal discipline, and a steady cadence of learning and adjusting as you go.

In the end, the taco truck is a portable classroom where every service teaches you something about efficiency, hospitality, and the stubborn, practical business of feeding people well. The permits you secure are not barriers but signposts that you are building something enduring. The vehicle you equip is more than metal and panels; it is a moving kitchen that must be designed for safety, cleanliness, and speed. The launch is not a one-off event but the beginning of a relationship with your community—an ongoing invitation for people to gather around a hot plate, savor a bite, and share a moment that makes your truck worth chasing through traffic and weather. Growth, when pursued with the same careful planning that got you to opening day, becomes the ability to repeat success in new neighborhoods, to broaden the menu without sacrificing what made the original tacos special, and to balance ambition with the discipline of a well-run operation. If you keep that balance—the legal protections, the practical kitchen realities, the customer-focused experience, and the thoughtful, data-informed approach to expansion—your taco truck will not merely exist; it will endure, season after season, as a familiar, welcome neighbor in the communities you serve.

Final thoughts

Building a taco truck that resonates with city life is about blending a clear purpose with practical execution. Start with a focused concept and audience, translate that into a compact, efficient kitchen, and secure permits while designing a launch that leaves a memorable, positive impression. As you grow, stay nimble: refine the menu, expand in steps, and keep your brand consistent across locations and marketing channels. With deliberate planning, solid design, and proactive growth strategies, your taco truck can become a trusted daily stop for urban commuters and curious weekend adventurers alike.