If you crave vibrant street flavors while weaving through city life, salsa fresca is the heartbeat of a taco truck you can trust. This guide unpacks four essential threads that keep taco truck salsa both delicious and practical for urban commuters, outdoor enthusiasts, small business owners, and first-time buyers alike: an authentic salsa fresca foundation, rock-solid food safety and sanitation standards, smart sourcing and procurement strategies, and clear regulatory compliance steps. By blending a time-honored recipe with modern safety practices, local supply networks, and straightforward licensing paths, you’ll be well positioned to deliver fresh, crave-worthy salsa on the go. Each chapter builds on the last, linking the art of making bright, crisp salsa with the realities of operating a mobile or freelance food venture in a bustling city. You’ll learn how to keep your salsa tasting bright from first bite to the last scoop, how to source ingredients without breaking the bank, and how to stay compliant so you can focus on serving happy customers. From the salsa fresca basics to the paperwork that keeps your cart compliant, this article translates traditional street food wisdom into practical steps you can take today. Whether you’re a weekend warrior with a dream cart or a startup chef leaning into the mobile economy, these insights help you deliver a consistent, high-quality product while navigating the unique demands of urban environments. Let’s explore how each chapter contributes to a holistic, city-friendly approach to making taco truck salsa that shines on every busy corner.

Salsa Fresca on Wheels: The Authentic Foundations Behind Taco Truck Salsa

On a sun-warmed curb where steam from grills mingles with the scent of citrus and char, a taco truck’s salsa does more than add brightness to a bite. It announces the cook’s philosophy: freshness without fuss, speed without sacrifice, and a respect for local growers that keeps the flavors honest. The salsa fresca you see on these streets is not a mere condiment; it is a portable manifesto of street-level cooking. It’s bright, it’s chunky, and it carries a sense of place in every diced tomato. The salsa most taco trucks serve is typically salsa fresca, sometimes called pico de gallo or salsa cruda, a raw, vibrant blend that relies on balance as much as bite. To build this on the go, you need not only a precise palate but a preparation rhythm that aligns with the truck’s pace and the archive of safety standards that govern any mobile kitchen. The foundations here are simple and timeless: ripe tomatoes that offer sweetness and acidity, a white onion that frames the mix with bite, fresh cilantro for aroma, jalapeño or serrano for heat, lime juice for brightness, and salt to pull all the flavors forward. The process honors the vegetable’s integrity, keeping the pieces chunky and the flavors distinct rather than blended into a purée. The result is a salsa that can be plated quickly, travels well, and wakes up the palate as tacos emerge from the grill, hot and sizzling.

Begin with the essence of the salsa fresca: the ingredients. The standard, street-ready ratio leans toward a bright composition that showcases the produce’s character. Four medium ripe tomatoes, chopped to roughly half-inch dice, form the base. The tomatoes contribute sweetness and acid, the backbone of the dish. A half onion, finely diced, adds a sharp edge that counters the fruit’s sweetness and heightens the crisp texture. One to two jalapeño peppers, seeded and minced, provide the heat. If you want milder salsa, Omit the seeds and membranes; if you crave more intensity, leave a few seeds intact. A half cup of fresh cilantro leaves, chopped and stems either torn away or finely minced, delivers that classic cilantro aroma without turning the mix grassy. Two cloves of garlic, crushed or minced, are optional but welcome for a sharper bite, especially in more robust taco configurations like carne asada or al pastor. A lime’s worth of acidity—juice from one to two limes, about two to three tablespoons—adds life and luminosity. Finally, a pinch to a half teaspoon of kosher salt (to taste) helps awaken the flavors and binds the mixture to the tortillas you’ll serve it with.

In practice, the method mirrors the tempo of a street kitchen. Start by preparing the produce as you would for any quick service: wash everything, then core and dice the tomatoes. If the tomatoes are especially juicy, you can seed them and lightly blot with a paper towel to manage moisture; this reduces watery runoff that can dilute the bright character you want. The onion should be diced finely enough to mingle with the tomatoes but not so small that it blends away. The jalapeños demand careful attention: wear gloves if possible, remove the seeds and membranes to dial down heat, then mince until you achieve a consistent, small dice. Cilantro should be chopped with a light touch to avoid bruising the leaves; you want aroma rather than a green mass. If you choose to add garlic, mince it finely to distribute its bite without creating raw garlic pockets that dominate the mix. As the components come together, drizzle in the lime juice evenly and sprinkle the salt across the surface. Gently fold the mixture to preserve the chunkiness while ensuring every piece is evenly seasoned.

Now comes the crucial moment: rest. A short rest of 15 to 30 minutes at room temperature allows the flavors to mingle. It’s a quiet time in the busier hours of the truck when the sizzle from the grill and the hiss of hot tortillas can distract from the salsa’s perfume. Resting is not about cooking; it is about unifying. The lime’s acidity blooms with the tomatoes’ natural sugars, the onion’s bite softens slightly, and the cilantro releases its fragrance in a way that only a little time can coax out. If you’re making ahead, refrigerate the salsa for up to 24 hours and bring it back to room temperature before serving to recapture its aroma. The texture should remain chunky, with vegetables retaining distinct edges rather than collapsing into a mush. If, after resting, the salsa seems watery, you can tilt the bowl and spoon off the excess liquid, then give it a gentle stir to re-center the ingredients. These small adjustments are the difference between a professional, chef-like finish and a home-style mash.

What makes a taco-truck salsa distinctive goes beyond the recipe. It is the relationship between the salsa and the other components of the plate. The salsa’s brightness must cut through the richness of grilled carne asada, al pastor, or fried fish, while its crisp texture offers a contrast to the soft tortillas and juicy fillings. It should hold up against a squeeze of lime and a handful of cilantro in each bite. Texture matters as much as flavor. The chunkiness invites spoons and chips, and a quick toss just before serving keeps the pieces from matting together as the truck rattles along. This balance is what travelers remember most, the little zing that accompanies a successful taco. The concept of immediacy—the ability to produce a fresh, bright salsa without long simmering or heavy preparation—anchors the street-food ethos. The research behind this approach notes that salsa fresca preserves the crispness of vegetables and the natural acidity of citrus, delivering a product that tastes of its ingredients rather than of artificial additives or heavy processing.

The discussion of texture and balance naturally leads to a few practical considerations that operators can apply without complicating the workflow. Tomato selection matters. Heirloom tomatoes bring color and nuanced sweetness, but their higher juice content can introduce more liquid. Roma or plum tomatoes are often drier and hold their shape well, which helps keep the salsa from becoming soupy in warm climates. A mix of tomato varieties is an option if you want both vivid color and a manageable moisture level. If you encounter off-season tomatoes, the flavor can still be brightened with careful seasoning and a touch of sugar or honey to balance acidity, but the ideal is always fresh, well-flavored fruit. The jalapeño’s heat can be modulated by seeds and membranes. If you’re serving to a mixed crowd with varying tolerance, consider offering a mild version with all seeds removed and a spicier version in a separate bowl. The lime’s acidity should taste clean and tangy rather than sharp and sour; if the tomatoes are particularly sweet, you might reduce lime juice slightly to maintain a cohesive flavor.

In discussing procurement and production, sustainability and practicality intersect. Local sourcing of tomatoes, onions, and peppers enhances flavor and reduces the carbon footprint from transport. It also supports the truck’s narrative: a vendor who buys close to home and turns seasonal produce into daily dishes. When fresh fruit is scarce or price-prohibitive, a backup plan is to use high-quality canned tomatoes in an emergency—ideally labeled with no added salt or sugar and drained thoroughly. This approach should be a last resort, not the default, because the flavor and texture differ noticeably from fresh ingredients. The guidance here emphasizes choosing organic or locally grown items when feasible, washing produce thoroughly, and ensuring everything that touches the food adheres to high cleanliness standards. Aroma, texture, and brightness should guide every decision, from the choice of tomato to the final sprinkle of salt.

For operators looking to connect this recipe to a broader operational philosophy, there is value in embracing a sustainable practice framework. A practical, truck-ready reference point can be found in discussions of mobile food-truck sustainability, which emphasize waste minimization, energy efficiency, and responsible sourcing. See sustainable-practices-mobile-food-trucks to explore strategies that align with a vivid, on-the-move salsa program while reducing environmental impact. This link serves as a bridge between culinary craft and responsible business practice, reinforcing the notion that a great salsa doesn’t just taste better; it travels better, too.

Beyond the basic green, red, and white of the ingredients, a few variations can expand a truck’s salsa repertoire without turning the menu into a swamp of options. A roasted-tomato version brings smoke and depth for taco configurations that lean toward char and fire. A fruit-forward twist—small, diced mango or pineapple folded in at the end—offers a tropical brightness that pairs beautifully with pork or shrimp tacos. If heat needs to be dialed up, serrano peppers can replace jalapeños, or a small amount of fresh jalapeño juice can be added to intensify brightness without increasing particulate heat. Each variation should still maintain the core values: fresh, chop-friendly texture; balanced acidity; and a clean finish after a short rest. The channel to the customer remains the same—a bright, vivid salsa that tastes like it was made moments before serving, even if it was prepared earlier in the day.

The chapter’s considerations also intersect with safety and regulatory realities that govern mobile operations. The salsa must be kept at safe temperatures to minimize microbial growth. Refrigeration should hold at 4°C (39°F) or lower, with prepared salsa kept chilled until service. If the salsa is held at room temperature, it should not exceed two hours of exposure. Cross-contamination remains a constant concern: separate cutting boards for vegetables and proteins, regular hand-washing, and proper glove use are not optional add-ons but foundational practices. The server’s hands, the utensils, and the station’s surfaces all contribute to the final flavor and safety profile of the salsa. Staff training becomes an ongoing part of the business, not a one-time checklist; quick, repeated reminders help ensure that the freshest salsa is the freshest possible, day after day.

What ties all these threads together is an understanding that salsa fresca is more than a recipe. It is a performance of craft on wheels. The technique, the texture, the timing, and even the decision to rest briefly all speak to a larger narrative: that street food, when done well, elevates simple ingredients into something memorable. The salsa’s brightness must lift each taco, and its texture should invite a quick fork or tortilla chip to capture a perfect bite. When a truck owner can pull a batch from the cooler, rest it briefly, and serve it with confidence, the salsa becomes a symbol of reliability in a world of changing street corners and shifting crowds. The rest of the chapter builds on this idea—how to source, store, and prepare the ingredients in harmony with safety guidelines, customer expectations, and the realities of a mobile kitchen.

In sum, the authentic salsa fresca foundations for a taco truck revolve around a few, carefully calibrated choices: produce that tastes like the place it came from, a chopping rhythm that preserves texture, a rest that brings the flavors into harmony, and a service plan that keeps the salsa as bright as the day’s first order. The practice is grounded in a balanced approach to heat, acidity, and salt, with the added responsibility of maintaining safety and compliance on the move. When these elements align, the salsa does more than accompany a taco; it accompanies a memory of a hot pepper sun, a smoky grill, and a street-side moment that tastes like home, even in a city that never stops turning.

External reference for further technique and safety considerations: https://www.foodnetwork.com/recipes/food-network-kitchen/canned-tomato-salsa-recipe-3897257

Fresh, Safe on Wheels: Crafting Taco Truck Salsa with Rigorous Sanitation

The allure of a taco truck salsa is immediate and unapologetic: bright colors, crisp textures, and a citrus-kissed bite that wakes up the taste buds in seconds. But the salsa that looks irresistible on the menu comes from a kitchen that treats safety as the first ingredient. This chapter follows the arc from a simple, authentic salsa fresca to a regimen of sanitation and regulatory awareness that keeps that vibrant flavor traveling safely from prep table to customer. For operators who want to optimize both speed and safety, the lesson is clear: freshness must be paired with discipline, and speed cannot outpace hygiene. In practice, the salsa that customers crave is the result of disciplined sourcing, meticulous handling, and purposeful storage as much as it is of the right knife skills or a memorable lime zing.

At the core, a classic street-side salsa fresca rests on a few dependable ingredients: ripe tomatoes, onions, a jalapeño or two, fresh cilantro, garlic, lime juice, and salt. The recipe reads like a promise of immediacy: wash, dice, mix, and serve. Yet that immediacy is possible only if every step acknowledges the perishable reality of raw produce. Tomatoes, onions, cilantro, and lime juice invite rapid microbial growth if left untreated or exposed to heat, air, or cross-contamination. The first strategic decision, therefore, is not only what goes in the bowl but how the ingredients are prepared, stored, and rotated through the day. The goal is not to overcomplicate the salsa but to protect its freshness long enough to reach every plate without compromise.

Consider the preparation sequence as a quiet choreography rather than a rushed montage. Begin with the tomatoes: choose firm, ripe specimens that are heavy for their size, with a bright aroma. Remove the cores, dice into uniform pieces, and hold the cubes in a clean, sanitized container. If.water content feels high, a brief resting time helps the juice settle and prevents a watery salsa, but that rest should occur in a chilled environment. The onions follow, diced small to maintain the characteristic bite without overwhelming the tomato sweetness. Jalapeños, when used, are seeded and minced with care; the seeds and white membranes carry much of the heat, so removing them standardizes heat across batches. Gloves remain essential here, not just to protect hands but to maintain the integrity of the ingredients—the moment you touch the jalapeño, the pepper’s capsaicin can transfer to skin and then to the eyes, nose, or other surfaces. Garlic is best used finely chopped or pressed to distribute its aromatic oils evenly. Finally, cilantro is chopped just before mixing to preserve its bright, grassy notes, and lime juice is added gradually to balance acidity with the natural sweetness of the produce. Salt is adjusted to taste, but the target is a balanced brightness that tastes like sunshine rather than vinegar.

The act of mixing is where safety begins to shape the texture as well as the flavor. In a large, clean bowl, combine the tomatoes, onions, peppers, cilantro, garlic, and lime juice. Toss gently to avoid mashing the tomatoes into a puddle, then taste and adjust. The salsa should retain its crispness—the hallmark of salsa fresca—so it benefits from a brief rest in the refrigerator after mixing. This rest, typically 30 minutes to 2 hours depending on batch size, allows the flavors to bloom without losing the coveted crunch. If the heat of the peppers is a concern, you can introduce a more modest amount of jalapeño and let customers opt for extra heat at the table. The salt should be the final touch, added to taste just before service to maintain a fresh, bracing profile.

From a safety perspective, the most important framework is temperature control and the avoidance of cross-contamination. Street vendors work with perishable ingredients in environments that demand vigilance. The salsa should be held at or below 4°C (39.2°F) when not being served, and it should not remain at room temperature for more than a two-hour window. The two-hour rule is a practical standard widely adopted for ready-to-eat, ready-to-serve foods. This means a batch that has sat out for two hours or more must be discarded and replaced with freshly prepared salsa. The consequence of neglect is not just a spoilage issue; it is a risk to public health that can undermine a day’s sales and a vendor’s reputation. In warm climates, where trucks operate under sunlit canopies for long hours, these limits become even more critical, and the urgency to keep everything cold is palpable.

A key element that often gets overlooked in vibrant, fast-moving street setups is the instrument of cleanliness. Cross-contamination is the enemy of safe salsa. The rule is simple yet powerful: use separate cutting boards and utensils for raw ingredients and ready-to-eat components. A dedicated prep area, with its own sink and storage, helps prevent drips and dribbles from raw onions or garlic from tainting finished salsa. Hands must be washed frequently, especially after handling raw produce, and gloves should be changed between tasks to prevent the transfer of microbes. Fresh cilantro and onions should be washed and patted dry; any residual moisture can dilute the salsa and provide a home for bacteria. The containers used to store salsa should be sanitized with food-grade cleaners and rinsed thoroughly before reuse. Regular cleaning schedules—daily, and more frequent during peak service—are not optional add-ons but essential routines.

Operator training is the backbone of consistent safety performance. The WHO and other health authorities highlight that many street vendors lack formal training in food handling practices. This reality elevates the importance of ongoing education, routine inspections, and practical drills on temperature checks, hand hygiene, and error-proofing storage. A well-trained team can translate the theory of safety into daily action: assessing the freshness of ingredients upon delivery, logging batch dates, and adhering to a disciplined rotation system so older salsa is used first and fresh batches take its place. A small wall calendar or a simple logbook can serve as the memory of the stall, recording when batches are prepared, when they are placed in refrigeration, when they are opened and closed, and when they are discarded. In this context, standards are not merely about compliance but about building trust with customers who come for flavor and return for reliability.

The sourcing approach to salsa also matters for safety and sustainability. Local farms and market vendors can provide tomatoes, onions, and peppers that travel shorter distances, arrive in better condition, and are more likely to be harvested at peak ripeness. Freshness translates into flavor; it also reduces the risk of spoilage during transit and storage. When fresh supplies are not available, the use of canned tomatoes can be a temporary substitute, but with caveats. Canned tomatoes can be introduced as a backup only after thorough draining and peeling, to reduce the risk of excess liquid and salt that can alter the texture of the salsa. The emphasis remains on using clean, additive-free ingredients whenever possible, with fresh lime juice preferred over bottled variants to preserve aroma and brightness. The role of herbs—cilantro, in particular—should be treated with care; fresh herbs deliver aroma and flavor that dried alternatives simply cannot match, and their inclusion in the salsa should be timed to preserve their peak green vibrancy.

From an operational standpoint, the chain of custody for salsa is almost as important as the recipe itself. If you can measure, you can manage, and that means establishing clear procurement protocols, storage practices, and rotation rules. A practical strategy is to prepare salsa in small batches that align with the business’s turnover rate. This minimizes the exposure of perishable ingredients to ambient temperatures and reduces waste. Each batch should be labeled with a prepared-on date and discarded after 48 hours, a threshold supported by international safety guidance for prepared ready-to-eat foods without preservatives. The intent is not to impose rigid, bureaucratic rituals but to preserve the integrity of the salsa’s texture and flavor while protecting customers. In this sense, the salsa becomes a living product that travels from the prep table to the customer’s plate with a story of careful handling behind it.

To connect practice and policy in a practical way, consider the equipment and infrastructure that support safe salsa service. The choices you make about prep spaces, refrigeration, sanitation tools, and storage containers have a direct effect on both flavor and safety. A robust setup includes a dedicated prep station for salsas, a properly sized refrigeration unit that can hold multiple batches at 4°C or cooler, and accessible sanitation stations for quick handwashing or glove changes. When it comes to equipment decisions, many operators rely on guidance that underscores safe, reliable, and economical choices. For example, see the guidance on choosing food-truck equipment wisely, which emphasizes selecting gear that supports hygienic workflows and efficient cleanup. This resource helps ensure that the kitchen on wheels remains a model of safety without sacrificing speed or taste: choose-food-truck-equipment-wisely.

In aggregating these best practices, the salsa becomes not only a dish but a demonstration of how street food can honor both flavor and health standards. The recipe remains the heart—the profile of ripe tomatoes, bright lime, and fragrant cilantro—while safety and sanitation provide the rhythm that keeps that heart beating throughout service. The balance is delicate but achievable: crisp texture and vibrant acidity, delivered safely by a team that understands the why behind every precaution. In the end, what customers taste is not only the sun-kissed brightness of the salsa but the confidence that their food, prepared in a mobile kitchen, is handled with care and accountability.

External reference: for a broader international perspective on safety requirements for street-vended foods, see the World Health Organization’s Essential Safety Requirements for Street-Vended Foods, which outlines clean work surfaces, potable water use, and cross-contamination prevention as foundational practices that align with salsa preparation on wheels. This resource reinforces the idea that authenticity and safety are not competing priorities but complementary forces that elevate street cuisine to a reliable, repeatable standard. External resource: https://www.who.int/publications/i/item/9789240035258

From Field to Fire: Building a Sourcing-Driven Salsa Identity for a Taco Truck

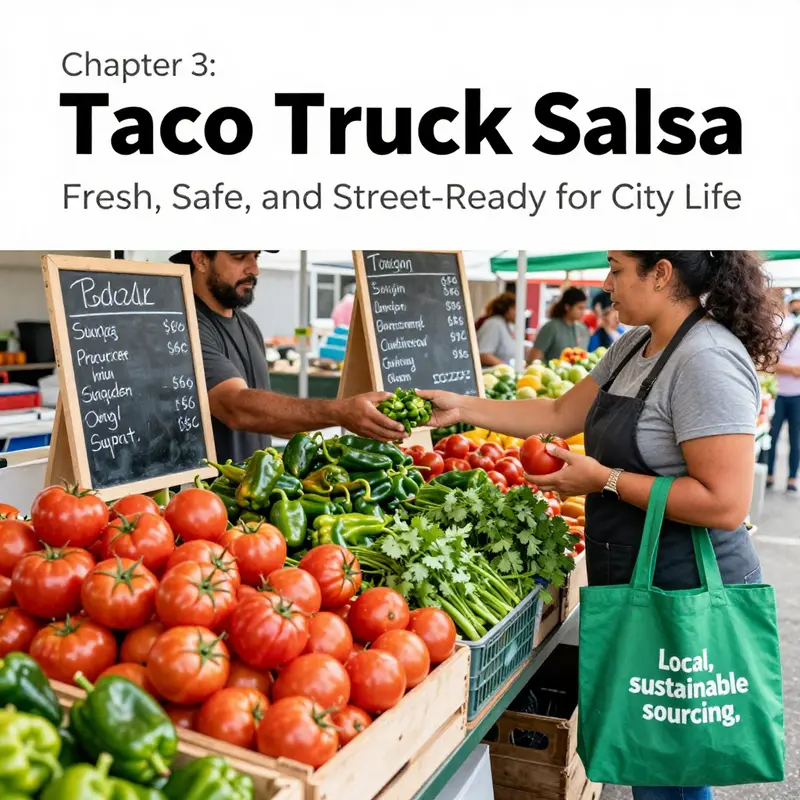

The salsa that greets a taco truck customer is more than a condiment; it is the opening line of a flavor story that travels with the truck from dawn markets to night-time curbside service. In a business where speed and freshness drive repeat visits, sourcing and procurement become as critical as the knife work in the kitchen. This chapter threads the practicalities of securing the right ingredients with the philosophy of a salsa that tastes like it came off a farm stand, even when it’s made in a compact vehicle on a rotating schedule. The core is simple: the best salsa starts with the best vegetables, but strong sourcing systems keep that standard consistent as markets change with the seasons and the route shifts from one neighborhood to the next. The result is a product that remains crisply bright, vibrantly aromatic, and reliably delicious, regardless of when or where a customer encounters the truck.

To appreciate the sourcing logic, start with the baseline: the classic street salsa—salsa fresca or pico de gallo. The essential trio of components—ripe tomatoes, white or yellow onions, and jalapeño or similar hot peppers—forms a canvas that invites brightness from cilantro and lime. The freshness thesis matters most here. Unlike sauces that simmer for hours and rely on measured heat, taco truck salsa is defined by its immediate crunch and the clean, garden-like finish of its acidity. The hold-this-image-in-your-head moment is a bowl of diced, sun-warmed tomatoes glistening with lime juice, a flutter of onion, a pepper’s tizzle of heat, and a handful of chopped cilantro that perfumes the air just before service. The sourcing strategy that supports this moment must be tactile, seasonal, and scalable.

Seasonality anchors the logic. In the Texas context, summers bring tomatoes at peak sweetness and juice, which translates directly into deeper flavor per bite. A robust supply chain for those months depends on local farms and farmers’ markets that can provide weekly or even daily deliveries with minimal lag. Partnerships built with nearby growers reduce the distance traveled, cut transit time, and preserve the vegetable’s crispness and aroma. The best operators treat local sourcing as a living network: an ongoing dialogue with a rotating cast of growers who understand the tempo of harvest and the truck’s schedule. This is not a mere purchase; it is a collaborative arrangement that reinforces the salsa’s identity as a fresh, local product. For operators aiming to deepen these relationships, a practical first step is to connect with the local sourcing ecosystem via dedicated vendor directories and cooperative platforms. A useful resource for identifying nearby suppliers and arranging regular pickups can be found at texasfarmersmarket.org/vendors, which provides directory access and contact information that helps a mobile unit align its orders with harvest peaks. See the link as a practical doorway into a regional web of growers who share a commitment to freshness and reliability.

When markets are abundant, the procurement cycle favors direct sourcing from farms, with a preference for seasonal tomatoes, red or white onions, and peppers grown under transparent farming practices. The goal is to minimize days from harvest to the salsa bowl, maintaining the vegetable’s snap and aroma. Fresh cilantro is another treasuring point; it is highly perishable and benefits from daily restocks or twice-daily deliveries during peak season. Lime juice—pressed fresh at the truck, never canned as a substitute for brightness—depends on a steady supply chain closely aligned to harvest calendars in nearby regions. In this model, the procurement team develops a lightweight, repeatable rhythm: weekly or twice-weekly orders that are timed to arrive just ahead of prep for the week’s route, with a buffer for unexpected demand spikes during special events or high-foot-traffic days.

For days when prime freshness is scarce—winter or off-peak windows—the best practice is to have a carefully considered backup option that preserves the salsa’s integrity without erasing the brand’s signature character. A properly vetted canned tomato option can serve as a contingency, provided it is low-sodium, simple, and thoroughly drained and rinsed before use. This approach offers stability in supply and price, reducing the risk of last-minute shortages that could compromise the salsa’s flavor profile. Yet even as canned alternatives are kept in rotation, they should be treated as secondary to the live vegetables and used to maintain coverage rather than as a go-to flavor baseline. The overarching philosophy remains clear: keep the core recipe as close to fresh as possible, and reserve canned tomatoes for controlled contingencies, not routine production.

Beyond the tomatoes, the other ingredients deserve thoughtful sourcing protocols. Onions should be bought from suppliers who can guarantee cold-chain integrity to prevent premature spoilage, especially when the truck depends on consistent performance from a portable refrigeration unit. Jalapeños or similar peppers should come in batches sized to match weekly menus, with attention to heat level—some days the truck might favor a milder batch to accommodate broader palates, other days a punchier chili note to wake up late-afternoon crowds. Cilantro, a coveted yet fragile herb, is best sourced from suppliers who can deliver daily replacements or two-daily shipments during peak season, ensuring that the herb’s essential oils remain vibrant rather than withering in transit. For lime juice, the brightest option is to juice on-site, but if the supply chain requires, reliable, simple, unadulterated limes sourced from nearby growing regions can keep the citrus aroma intact when fresh fruit is limited.

From a logistical perspective, the procurement system should be designed to harmonize with the truck’s schedule. In practice, this means forecasting demand for each service window, estimating ingredient usage for anticipated sales, and building a buffer that accounts for weather, traffic, and event-driven surges. The model is lean, yet flexible enough to accommodate a last-minute delivery or a market stall that carries a higher-than-average weight of tomatoes one week. For fleets running multiple units or visiting stand-alone markets across a city, a centralized procurement plan helps maintain uniform quality and flavor across all units. Temperature-controlled storage, separate prep space for salsa ingredients, and strict cross-contamination protocols are non-negotiable elements in the supply chain. The objective is to keep the ingredients in pristine condition from the moment they are unloaded until the moment the salsa leaves the bowl for the first bite.

Sustainability threads through the sourcing approach as well. A zero-waste practice invites operators to repurpose trimmings—onion peels, pepper stems, cilantro stems—into vegetable stock or compost. This reduces waste while supporting a kitchen culture that respects the ingredients’ full life. In a more formal sense, certification and verification become signals to customers that the business is serious about ethics and quality. Chapters of this book have discussed certification layers and traceability, and in the salsa supply chain those signals translate into trust—trust that the salsa is not only delicious but also produced with care for the people who grow, pick, pack, and transport every component. While multiple locations may rely on wholesale distributors for bulk orders, many operators still prize the artistry of sourcing: a network built around timely harvests, conversations with growers, and a shared commitment to freshness.

An important practical facet of this approach is documentation. Even in a small mobile unit, keep a record of supplier contacts, delivery days, and batch notes for the salsa components. A simple ledger of which farms supplied tomatoes and cilantro for each week, along with notes on taste and texture, supports continuity as staff change and yields vary. This practice matters not only for consistency but also for safety and compliance. The more transparent the supply chain, the easier it is to defend quality decisions when customers ask questions about where the ingredients come from and how they were handled before reaching the salsa bowl.

In the broader context of a taco truck’s operation, the sourcing narrative helps customers understand the decision to keep the salsa fresh and unheated. The flavor story is anchored in the field-to-table ethos: the tomatoes are radiant because they were picked at the height of ripeness, the onions deliver a crisp snap because they spent little time in transit, and the lime’s bright acidity arrives from careful handling rather than preservation. When customers taste the finished salsa, they are experiencing a chain of decisions that honors seasonality, locality, and integrity. The key is to translate those decisions into a dependable, repeatable process that can travel on wheels as confidently as the truck itself. The sourcing strategy described here is not a one-off plan but a living framework, adaptable to market shifts, event schedules, and the evolving tastes of the truck’s regulars.

To close the loop between procurement and flavor, many operators find value in a concrete, local-first sourcing mindset reinforced by a simple, scalable supplier map. This map helps plan orders around harvest calendars, ensuring that every batch of salsa reflects the best available ingredients. It also creates a reliable backend that supports a flavorful front of house. For those seeking a practical starting point to expand local supplier networks, the online directory at texasfarmersmarket.org/vendors provides pathways to verified local producers, enabling truck owners to align their menu with seasonal availability and community supply lines. This approach not only sustains flavor but also strengthens the truck’s identity as a moving ambassador of local agriculture, a narrative that customers recognize and appreciate with every bite.

In the end, the salsa on a taco truck is more than a recipe; it is a curated experience that hinges on the quality and reliability of its ingredients. The sourcing and procurement decisions behind that experience shape everything from the salsa’s texture to its aroma, from its heat level to its acidity, and even to the rhythm of the truck’s service. By cultivating local connections, planning for seasonal shifts, and maintaining a disciplined yet flexible supply chain, operators ensure that their salsa remains crisp, bright, and unmistakably authentic no matter where the road takes them. This, in turn, reinforces the truck’s reputation as a trusted source of fresh flavor, a rolling demonstration of how thoughtful sourcing fuels not just meals, but community and continuity on the street.

External resource for practical contingency planning: for a tested approach to using canned tomatoes when fresh supply is constrained, see a comprehensive guide to canned tomato salsa recipes and their practical applications. [External resource] https://www.foodnetwork.com/recipes/food-network-kitchen/canned-tomato-salsa-recipe-3897257

Salsa on Wheels: Navigating Compliance, Permits, and the Path to a Legal Taco Truck Kitchen

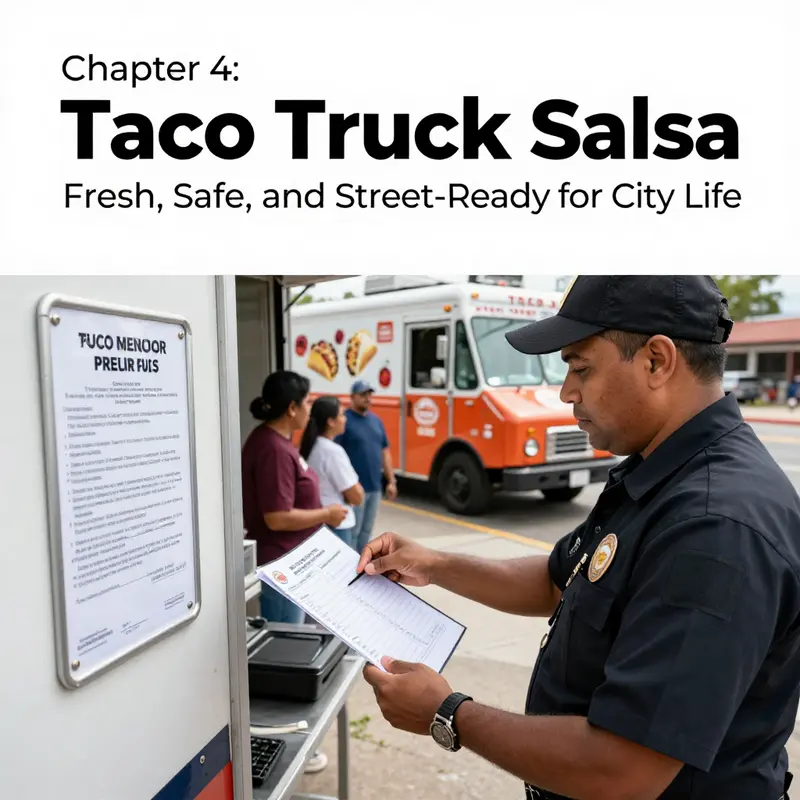

The aroma of fresh salsa on a taco truck draws crowds to the curb, but turning a recipe into a rolling business means balancing flavor with responsibility. A mobile salsa operation lives inside a framework of permits, inspections, and documented processes that protect customers and sustain growth. The goal is simple: safety and service can travel together as the truck rolls from market to festival to street corner.

At the federal level, the focus is safe handling, sanitation, temperature control, and preventing cross contamination. For operators who process or package salsa beyond immediate service, a preventive controls mindset helps identify hazards, define controls, and establish monitoring and verification. Even when most activity happens on the truck, thinking in terms of hazards and preventive steps creates a culture of readiness rather than last minute fixes.

State and local requirements translate those ideas into concrete licenses and permits. In many places you will need a business license, a health permit for a food establishment, and a mobile vending permit. A commissary agreement with a licensed kitchen is common, ensuring reliable washing, storage, and access to water and waste disposal. Fire department clearance and vehicle inspections may also apply, especially if propane or ventilation is involved.

Packaging and labeling rules vary by jurisdiction. If salsa is sold in consumer containers, you may need an ingredient list, net weight, the name and address of the facility, a lot or batch code, and a best by date. Even for salsa served directly from the truck, clear information about ingredients and allergens helps protect customers and reduce recalls.

A well chosen commissary matters. It anchors the operation to a compliant space for cold storage, proper warewashing, and routine sanitation. The relationship should be formalized in a written agreement that covers access times, water and electricity, waste handling, and cleaning expectations. A strong commissary reduces variability and simplifies inspections.

The safety plan is the heart of compliance. A written plan or preventive controls approach maps the flow from receipt to service, identifies hazards at critical points, and defines monitoring and corrective actions. Temperature control is non negotiable: keep ready to eat salsa at or below 40 degrees Fahrenheit (4 degrees Celsius) and log temperatures at storage, prep, and display. If occasional hot holding is used, a separate protocol is needed.

Allergen controls and supplier verification deserve special attention. An explicit plan to prevent cross contact, clearly designated utensils, and dedicated prep spaces protects customers with allergies. Maintaining supplier certificates and batch records supports traceability and helps with recalls if needed. A responsible person should review safety steps and keep inspection readiness in mind.

Documentation ties everything together. Licenses, permits, insurance, commissary agreements, training records, sanitation logs, and temperature charts form a portfolio that inspectors may request. A centralized system, whether digital or manual, reduces disruption when actions are required and speeds up response during audits.

Operational readiness is practical: decide the business structure, register the name, and obtain a federal identifier if needed. Map the licensing path in your city or county, pass the health inspection, ensure vehicle compliance, and arrange staff training. Prepare a safety plan early and tailor it to the truck workflow. Create labeling templates and signage that clearly communicate ingredients and allergens. Verify insurance coverage and workers’ compensation when you have employees.

To support ongoing compliance, use practical templates and tools. A basic preventive controls outline can be adapted to a mobile setup, detailing process steps, hazards, critical limits, monitoring, corrective actions, and verification. A sanitation schedule, temperature logs, and supplier logs help sustain discipline and enable quick response to questions from inspectors. A recall plan, though hopeful never to use, formalizes your path for crisis situations.

The result is smoother operations that can travel from market to festival with confidence. A well governed salsa truck can focus on flavor and hospitality while maintaining safety. The key is to build the compliance backbone early, keep it visible in daily routines, and treat inspections as opportunities to demonstrate care for customers.

As you plan expansion to multiple locations, align practices with broader industry standards and sustainable operations. Consider easy, scalable practices that reduce waste and improve energy use on the road. External resources and templates can provide guidance on workflows, equipment layouts, and procurement choices that support compliance without slowing service. The combined effect of a clear safety plan, thorough recordkeeping, and a strong commissary relationship is a resilient platform for long term success. When salsa is bright, fresh, and consistently safe, the truck can keep rolling and customers keep coming back.

For readers seeking external guidance on packaging and shelf life, consult practical resources from food safety authorities and industry sites. Always align packaging and labeling with local requirements before producing packaged salsa for sale. The overarching message stays the same: flavor and safety travel together, and a compliant operation opens doors to wider opportunities.

Final thoughts

Mastering taco truck salsa is about more than a great taste. It’s about a thoughtful balance of authentic preparation, strict safety practices, dependable sourcing, and clear regulatory readiness. Start with a bright, fresh salsa fresca, respect cold-chain needs, and keep your workspace clean and organized. Build relationships with local farmers and suppliers to sustain quality and price stability, then secure the licenses and permits that show customers you care about their safety as much as the flavor you deliver. With these pillars in place, you’ll be ready to bring vibrant, crave-worthy salsa to city streets—one confident scoop at a time.