Urban life thrives on portability, value, and flavor you can crave on the go. Taco truck style tacos deliver exactly that: tortillas warmed to order, a protein-forward filling, and a duo of salsas that bring brightness and depth, all wrapped in a hands-on, fast-workflow format. This guide threads together culinary technique, equipment considerations, sourcing, pricing, safety, and cultural context so you can translate the street-food experience into a compact, mobile operation that works in busy city environments. Whether you’re commuting between homes and offices, pursuing outdoor adventures with a quick bite, running a small business out of a pickup, or exploring a first-time pickup purchase, these chapters offer actionable steps tailored to real-world constraints. You’ll learn how to optimize a tiny kitchen footprint without compromising flavor, design a menu that travels well and scales, price for profitability on high-turnover days, and navigate the safety and regulatory landscape while honoring regional flavors and customers who expect consistency and character. Each section connects back to the core culinary paradigm: masa-based tortillas, a concise set of regional protein preparations, bright red and green salsas, fresh toppings, and a streamlined assembly-line flow that keeps lines moving and customers smiling.

The Kinetic Kitchen: Equipment, Layout, and Workflow for Authentic Taco Truck Assembly

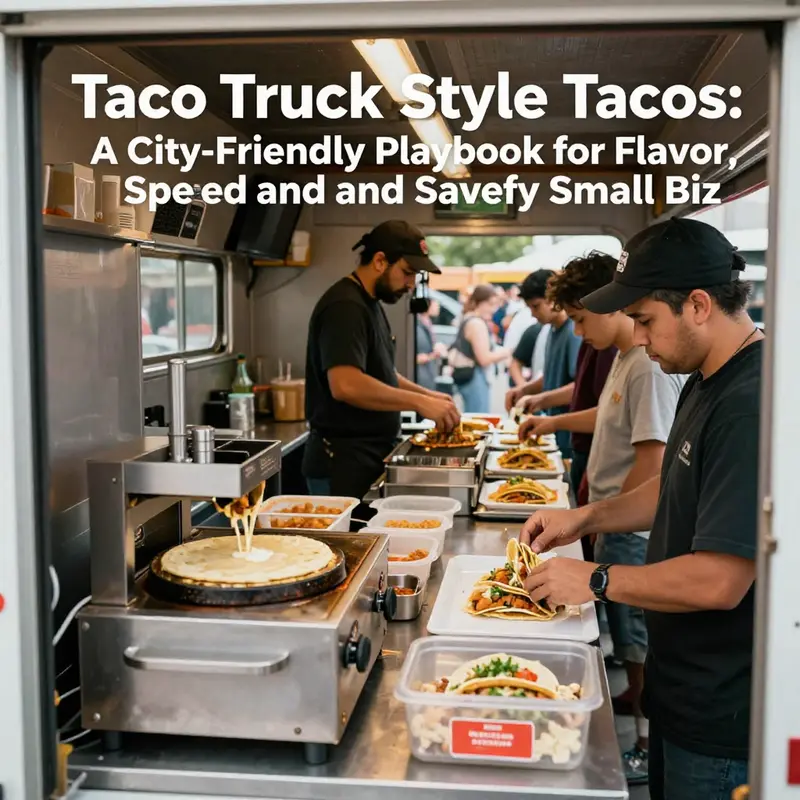

In a taco truck, the kitchen is a living system that translates heritage technique into a portable, high-turnover operation. The objective is simple in description but exacting in execution: deliver hand-assembled, masa-forward tacos with signature salsas and toppings, every order, every time. This demands a kitchen that breathes with efficiency, safety, and adaptability. It starts with the space itself—how it is divided, how heat and cold are managed, where tools live, and how the staff move through the line. It continues with a disciplined workflow that mirrors a street-side script: a steady, repeatable sequence that preserves the tenderness of a braised protein, the snap of a fresh garnish, and the clean brightness of salsa verde and salsa roja. The result is not merely a menu of tacos but a choreography that makes a crowded day feel manageable, even predictable, without sacrificing authenticity. The most essential idea is not to overcomplicate the setup but to optimize it for reliability and speed while staying faithful to the core culinary paradigm: small tortillas, protein-forward fillings, two complementary salsas, and a crisp, clean finish with lime and garnish that punctuate each bite.\n\nFrom the customer-facing front to the back of the house, the layout should be conceived as an uninterrupted flow. The front section, where orders are taken and a tortilla warmer waits, is more than a welcome point; it sets the pace. A tidy counter, a simple digital point-of-sale interface, and a clear menu board help customers order confidently and quickly. Keeping pre-made shells or warm tortillas within easy reach minimizes hand movements and avoids bottlenecks at service. The staff can greet guests, confirm special requests, and then turn the order into action without stepping away from the line. The same logic extends to the back of the truck, where the central cooking zone houses the core heat source. An electric griddle or flat-top grill provides consistent, controllable heat that suits both searing carne asada and caramelizing onions. It offers a degree of safety and predictability that is harder to achieve with open flame in a compact vehicle. A double burner electric stove supports sauces, beans, and rice—stability and control allowed by a steady, even simmer. An under-counter refrigerator keeps cilantro, onions, cheese, and marinated proteins within arm’s reach, reducing motion that can disrupt a quick service rhythm. A sink with running water and a hand-sanitizer station reinforces hygiene at the point of use, a critical factor when handling fresh produce, raw proteins, and ready-to-assemble tortillas.\n\nThe assembly line itself should resemble a well-practiced relay. A multi-tiered worktable creates distinct zones without creating physical seams that slow the line. A tortilla-warming station sits at one end; a meat station with pre-cooked, portioned proteins sits just beyond; a fresh-toppings area follows, offering chopped onions, cilantro, radishes, lime wedges, and two salsa bowls—one verde, one roja. A cheese shaker or dispenser is placed where a quick dusting can finish a taco with a bright, salty note. The line is designed so that a taco passes through each station in a single, repeatable motion: warm tortilla, add protein, top with salsa, crown with fresh garnishes, and finish with a squeeze of lime. The final plating must be simple but deliberate—tacos stacked on biodegradable plates or wrapped in parchment, with condiments offered on the side to avoid soggy tortillas at the point of consumption. This is not merely a preference for cleanliness; it is a practical tactic to preserve texture and taste as the line grows.\n\nUnderpinning this arrangement is a robust storage and utility spine. Wall-mounted racks keep spatulas, tongs, and cutting boards organized and within arm’s reach. Separate waste bins for grease, compost, and trash help maintain a clean, safe workspace and support sustainable practices that modern customers expect. Power remains a constant concern in mobile operations. Where possible, grid electricity supports the core equipment, but many trucks rely on generators to maintain flexibility across markets. The chosen power strategy should align with local regulations, the truck’s electrical load, and the expected peak service times. Regular maintenance of electrical components, fuel systems if generators are used, and ventilation considerations is non-negotiable. A calm, tidy utility zone behind the scenes keeps water lines, soap dispensers, and sanitizer supplies within arm’s reach but out of the primary line of service, preserving speed while maintaining hygiene.\n\nProximity, of course, is not only about physical distance but about the sequence of tasks and the clarity of the process. A modular cart concept can add flexibility, allowing operators to reconfigure the workspace for events that vary in size or shape. A cart that can be pulled into a different configuration for a festival or a street fair keeps the core workflow intact while accommodating a higher turn rate or a more complex menu. The ergonomic logic here is straightforward: every item, every tool, and every ingredient should have a defined home that minimizes reach, reduces cross-path movement, and limits unnecessary handling. The result is a kitchen that feels linear and purposeful, even during a rush, with less fatigue and more consistency in the final taco.\n\nWithin this framework, the workflow becomes a living protocol rather than a set of discrete tasks. A pull-system approach helps keep waste low and ingredients fresh by generating only what the line needs for the immediate moment. In practice this means staging proteins in pre-portioned trays, heating tortillas in small batches, and preparing salsas in a way that their flavor can be refreshed throughout service without sacrificing texture. The pre-prep phase—marinating proteins like achiote-marinated al pastor with pineapple, grinding a fresh mix of spices for carne, and chopping onions and cilantro—helps shorten the service window. It’s a discipline that respects the intensity of rush periods while preserving the delicate balance of flavors that define authentic taco truck fares. The line then moves into the cooking and assembly phases, where precision matters as much as speed. Electric grills lend themselves to precise temperature control, producing a sear with depth and a crust that enhances aroma. The sauces simmer on a gentle flame, thick enough to cling to the tortilla but never so heavy that they overwhelm the filling. Fresh garnishes provide the final notes—crisp onion, bright cilantro, and the piercing citrus of lime—before a customer bites into a taco that feels assembled, not assembled-once-and-forgotten.\n\nIn terms of authentic assembly, technique matters as much as ingredients. Tortilla handling is a small but powerful ritual: warm the masa-based shell over direct heat for a brief, luminous moment so it yields a pliable, lightly blistered surface. Microwaving tortillas should be avoided; the moisture loss creates a soggy, lackluster texture. Meat preparation follows a family of classic methods. Al pastor, with a pineapple-adorned twist, reads as a nod to rotisserie technique, whether the spit is vertical or a diligent stovetop equivalent. Carnitas—slow-cooked until the edges crisp, then finished on the hot surface to reestablish a bite—offer a texture contrast that remains faithful to tradition. Carne asada brings brightness with citrus-forward marinades and quick searing, preserving the beef’s tenderness while giving a caramelized exterior. Sauces and garnishes must be accessible and balanced: two distinct salsas that offer heat, brightness, and acidity, plus a fresh, crisp topping set that can be tailored to heat tolerance and flavor preference. The customer’s customization is a familiar hallmark of street food culture, and it should be anticipated rather than accommodated as an afterthought. Allow customers to choose spice levels, ask for avocado or extra cheese, and expect a consistent quality irrespective of the order’s complexity.\n\nEquipment choice anchors the entire operation. The best option for many operators is electric-powered taco carts that provide stable heat, controllable power usage, and safer operation in indoor or festival environments. The objective is to replace uncertain flame exposure with reliable, repeatable heat management while reducing fire risk and maintenance headaches. Of course, a truck must be prepared for the realities of mobile service: it should be possible to operate with either a generator or a direct grid connection, and the layout should support rapid energy transition between peak and off-peak periods. Maintenance and sanitation, meanwhile, should be integrated into daily routines rather than treated as afterthoughts. Regular oil changes for fryers or griddles, timely filter cleaning, and routine sanitation of cutting boards and work surfaces are essential. In a business where food safety and customer confidence hinge on cleanliness, a disciplined maintenance plan is non-negotiable. The idea is to prevent issues before they appear, so service remains smooth and predictable rather than reactive and stressful.\n\nThe human element cannot be overlooked. Training is an ongoing investment, even in a small operation. Staff should learn the precise order of operations, the expected yield of each batch, and the correct method for assembling each taco. A shared vocabulary, crisp station boundaries, and a culture of checking work at each step contribute to consistency. In many border towns and urban centers, the street-food ethos includes generous portions coupled with personal tailoring of heat and toppings. The operator’s job is to translate that ethos into a reliable system that can scale with demand without losing soul. One practical measure is cross-training across stations so team members understand the entire flow. When everyone understands the sequence—from tortilla warmth to final squeeze of lime—the service becomes more resilient during a rush and easier to train new staff.\n\nAll of this aligns with the practical guidance that has shaped contemporary mobile kitchens. The emphasis on electric-powered carts reflects safety, heat control, and environmental responsibility. It also aligns with regulatory contexts that favor controlled energy use and reduced smoke in enclosed spaces. A thoughtful layout, paired with a well-delineated workflow, supports consistent product quality and a better guest experience. It also simplifies the complex economics of a taco truck: better yield from meat, a reliable service speed that minimizes labor costs, and a waste profile that remains manageable even as orders scale. The chain of decisions—from equipment choice to the placement of a hand-wash station—becomes a single thread that binds the entire operation into something that feels effortless to customers and sustainable for operators.\n\nTo those charting their own course, a practical reminder is to explore the equipment decision in depth as part of a broader plan. A concise resource on choosing food truck equipment can offer a structured framework for evaluating heat sources, cold storage, and workflow compatibility. For readers who want a targeted guide, consider the resource Choose Food Truck Equipment Wisely, which distills the core considerations into an accessible checklist while you map your truck’s layout and staffing model. Choose Food Truck Equipment Wisely This link offers a grounded perspective on how equipment choices ripple through safety, cost, and service quality, without locking you into a single supplier or design.\n\nIn the end, the authentic taco truck experience rests on the harmony between tradition and optimization. The tortillas must speak of masa and heritage; the fillings must carry the memory of regional braises and street-side char; the salsas must balance heat with brightness; and the workflow must protect these elements while embracing mobility and high turnover. A well-planned front, a disciplined core, and a responsive line combine to deliver more than convenience. They deliver a compelling, memory-rich bite that travels well and leaves patrons satisfied, curious, and ready to return. The street-food energy—geared toward speed, centered on hand-assembled craft, and grounded in family-style technique—remains intact when equipment is chosen with an eye toward safety and reliability, when layout honors movement and reach, and when a team is trained to execute with calm precision.\n\nFor readers seeking further technical orientation on how to translate these principles into a practical, field-ready blueprint, consult external resources that synthesize equipment, safety, and operational best practices for taco carts and mobile kitchens. A recommended external reference that offers a broader, professional perspective on taco cart guidance is accessible here: https://www.foodtruckinsider.com/taco-cart-guide/ . This resource can complement the hands-on considerations discussed in this chapter by offering additional perspectives on layout, power planning, and compliant operation in diverse environments.

From Masa to Mastery: Core Ingredients and Bold Flavor Profiles for Taco Truck–Style Tacos

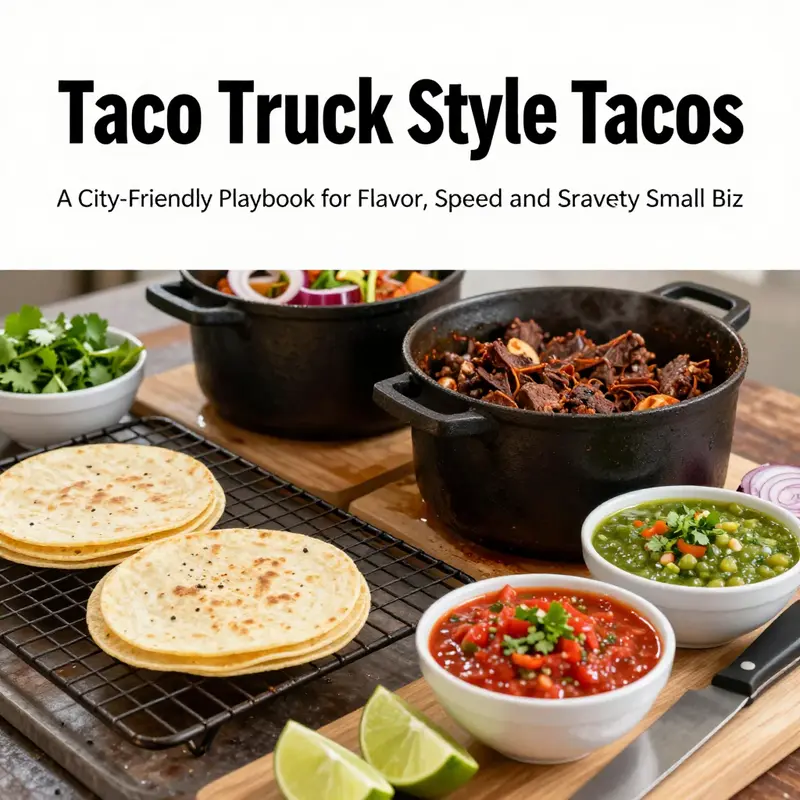

The heartbeat of a taco truck lives in a focused set of core ingredients. The tortillas are the canvas, the meats bring personality, the salsas supply heat and brightness, and the toppings finish with salt, texture, and acidity. When these elements are balanced and consistent, service travels well from prep to street. This chapter outlines the four pillars—tortillas, meats, salsas, and toppings—and shows how they relate to a scalable flavor system for a mobile operation.

Tortillas: start with masa harina that has been nixtamalized. Hydrate the dough just enough to form a cohesive ball that holds together. A practical ratio is roughly 2 cups masa harina to about 1 1/4 to 1 1/2 cups warm water, plus a pinch of salt. Rest the dough briefly, then press to around 1/16 to 1/8 inch. Cook on a hot comal at 400–450°F for about 45–60 seconds per side; keep warm to preserve pliability. Salt after cooking if needed.

Meats: common core options—carne asada, al pastor, carnitas—each benefits from marination, careful cooking, and proper resting. Carne asada leans bright with garlic and citrus and sears hot for a caramelized crust. Al pastor marries chile, achiote, and pineapple for sweet-smoked depth. Carnitas braises pork with fat and aromatics, then finishes with a gentle crisp. Slice or shred against the grain for easy tortilla wrapping and consistent bites.

Salsas: Roja (roasted tomatoes and chiles), Verde (tomatillos and green chiles), and Pico de gallo (tomato, onion, jalapeño) provide heat, brightness, and texture. Creamy options like crema or avocado crema balance fat; cotija adds a salty finish.

Toppings: onion, cilantro, lime, radish, cotija, crema, and optional greens or cabbage. These micro-notes deliver crunch, aroma, and a finishing lift that makes the bite feel complete.

Operational rhythm: in a compact truck, run a two-meat, two-salsa baseline with a crema or avocado option and a tight set of toppings. Prepare salsas and toppings in consistent portions; batch-cook meats but portion them cleanly for fast assembly. The goal is a fast, reliable line that still feels handmade.

Sustainability and community: prioritize fresh, local ingredients where possible, minimize waste, and choose packaging that suits mobile service without sacrificing speed. This framework is designed to scale from a single operator to a small fleet while preserving the core identity of taco truck cuisine.

From Sourcing to Sizzle: Mastering Taco Truck Style Tacos in a Street-Food Economy

The street-food economy has transformed with surprising speed, and taco trucks sit at the center of that transformation. What looks like a simple sandwich wrapped in a warm tortilla is, in reality, the product of a complex dance between design, sourcing, price, and daily operations. The chapter that follows does not pretend to be a mere recipe guide; it traces the lifecycle of taco truck style tacos from the moment a truck is chosen or built to the moment a customer bites into a hand-assembled tortilla that carries both heritage and innovation. The core ideas are straightforward: craft a reliable, portable kitchen that produces consistent tortillas and fillings, price your offering to reflect quality and convenience, and stay agile in a market that rewards speed, taste, and adaptability. Yet beneath that simplicity lies a web of decisions about where to source a vehicle, how to finance it, what standards must be met, and how to optimize routes, menus, and customer experience for maximum flavor and profitability.

Sourcing stands as the first and most consequential decision in this chain. The global market for mobile food units has grown substantially, driven by demand for authentic, affordable, and convenient meals. For many operators, reliable sourcing begins with a decision to work with international suppliers who specialize in turnkey or modular kitchen vehicles. China has emerged as a dominant source, particularly for operators who need a balance of price and capability. Within this landscape, industrial clusters in Henan and Shandong illustrate how scale and specialization can compress lead times while preserving critical standards. Henan, home to a large share of commercial vehicle fabrication and stainless steel processing, offers suppliers who can integrate refrigeration, counters, sinks, and exhaust with an eye toward durability and food safety. Shandong contributes through proximity to major shipping ports, which translates into faster delivery cycles and competitive freight terms. The result is a marketplace where a prospective taco operator can procure a vehicle that is either a standard platform or a deeply customized kitchen on wheels with a layout designed to optimize a small but highly efficient assembly line.

Choosing a supplier is rarely about price alone. A robust due-diligence process weighs technical capacity, reliability, and post-sale support. Buyers should request verifiable information on material quality, in particular corrosion-resistant stainless steel and food-safe surfaces. They should confirm compliance with U S health and safety standards, including NSF compliant surfaces and NFPA 96 compliant ventilation. A dual-voltage electrical setup compatible with American power grids can eliminate a surprising number of headaches during operation, and modular interior layouts provide long-term versatility for tacos, coffee, BBQ, or other street-food ambitions. These considerations matter because a truck that ships with a flexible interior not only supports a more resilient menu but also mitigates risk when a market shifts or a concept pivots. A modular build, for example, can transform a taco bar into a coffee kiosk or a miniature barbecue setup without a full retrofit, helping an operator adapt to seasons, neighborhoods, or competition.

A separate but equally important decision point centers on the choice between new and used units. Used trucks can offer a quicker path to market and a lower upfront cost, yet they bring greater risk. The absence of complete maintenance histories, potential compliance gaps, and hidden mechanical issues can erode margins and disrupt service. A disciplined procurement approach — insisting on maintenance records, inspection reports, and proof of regulatory compliance — is essential when considering a used unit. In today’s market, door-to-door delivery timelines for verifiable used units can be 35 to 60 days, a window that still aligns with many operators who plan around seasonal demand or event schedules. The key is to pair speed with certainty: a trusted seller, transparent documentation, and a clear plan for post-sale service and replacement parts.

Alongside the vehicle itself, a thoughtful view of logistics underpins profitability. The street-food economy rewards mobility and reliability. Operators who optimize routes and timing, using real-time data about foot traffic, weather, and local events, tend to outperform peers who operate with static assumptions. A city like Austin exemplifies how a food truck ecosystem can become a cultural force, with neighborhoods creating consistent demand for authentic street tacos and a cadence of events that sustains turnover. Even in markets with a strong dine-in culture, trucks win by offering speed, a focused menu, and a sense of place that is mobile yet familiar. For operators, that means designing not only a tortilla-centric menu but a logistics plan that minimizes downtime and maximizes the number of hot, ready meals that move per hour.

Beyond the chassis and the build, the operational heart of taco truck style tacos is the workflow in the kitchen. The classic approach emphasizes a small but protean protein lineup, fast yet flavorful marinades or braises, and a tight assembly line that delivers a hand-assembled tortilla with a carefully composed filling. The tortillas themselves draw on masa harina or nixtamalized corn, prepared fresh or semi-prepared with consistent thickness and yield. When these elements come together in a truck designed for quick cleaning and easy sanitation, the result is a product that travels well, tastes bright, and maintains its integrity across dozens of servings. Salsas, of course, play a pivotal role. Typically two primary salsas accompany the routine — a red and a green — each with its own brightness and heat profile. Fresh garnishes finish the tacos, adding texture and contrast that enhance the eating experience in a handful of bites. The aim is not complexity for its own sake but a deliberate balance between boldness and restraint so that the tortilla, protein, and salsa speak clearly in each bite.

Pricing in the street-food economy is a layered calculation that reflects not just the cost of goods but the value delivered by speed, consistency, and location. Landed cost is a starting point: the purchase price of the vehicle, freight, insurance, duties, and any port handling fees must be recouped through sales margins that respond to local competition, consumer willingness to pay, and the cost of labor on the move. Currency risk matters when buying from abroad, and operators often mitigate this through forward contracts, hedging, or simply building a buffer into their prices. Financing options, whether through equipment loans or lease-to-own structures, help diversify capital allocation so that more resources can be directed toward high-impact functions like meat sourcing, salsa ingredients, or a robust refrigeration system. Warranty and post-sale support become essential in markets where downtime hurts more than a few hours of service. A reliable supplier relationship translates into access to spare parts and service networks, which in turn keeps the truck on the road rather than in the shop.

The economics of sourcing also intersect with menu design and portion control. In a typical taco truck setup, protein portions are small but flavorful, with a deliberate emphasis on center-of-plate notes rather than heavy bulk. That approach reduces food cost while preserving the perception of abundance. Salsas and garnishes must be meticulously prepared to maximize yield and minimize waste. Clean, efficient prep areas with robust refrigeration reduce spoilage and deliver a consistent product from one service to the next. In practice, this means investing in a compact, well-insulated cold chain, reliable two-compartment sinks for washing and sanitation, and a handwashing station that meets regulatory expectations without creating workflow bottlenecks. Ventilation and fire safety are non-negotiable for a mobile kitchen. NFPA 96 compliant ventilation systems ensure safe operation when high-heat cooking returns steam and smoke to the outside world, while an appropriate fire suppression system provides immediate protection in case of incidents. These elements are not cosmetic add-ons; they are core to the crew’s confidence and the business’s long-term viability.

The idea of a street-food operation as a constantly evolving system becomes more vivid when we consider the path from sourcing to service as a cycle rather than a linear process. A well-sourced truck is not just a rolling kitchen; it is a platform for repeatable performance. The interior layout matters because it governs speed and sanitation, not just aesthetics. A well-lit, easy-to-clean surface plan reduces cross-contamination risk and speeds up turnover. A modular design enables a small team to reconfigure the space for different events or menus, which is particularly valuable for operators who pivot seasonally or respond to community partnerships. The ability to deliver high-quality tortillas, bright salsas, and well-seasoned proteins in a compact, mobile footprint is what distinguishes a successful taco truck from a deeply discounted imitator. The fusion of craft with logistics is what allows a truck to survive the peripatetic tempo of the street-food economy, where a few minutes saved on the line can yield a handful of plates more per hour, and a handful of plates per hour adds up to a meaningful bottom line over a week or a month.

The social and cultural dimensions of taco truck style tacos are worth noting because they shape both demand and perception. A truck that is seen as part of a community, that respects local ingredients or local tastes, can earn devoted patrons who return not just for food but for the experience. In many markets, tacos are more than a meal; they are a ritual of neighborhood life. That social dimension translates into operational choices: a consistent schedule, a recognizable voice on social media, and a willingness to participate in community events. The street-food economy rewards operators who treat each day as an opportunity to engage with customers, learn from real-time feedback, and adjust the menu and service style accordingly. In turn, customers respond by showing up with confidence, knowing that the taco on the griddle comes with a traceable commitment to quality and safety.

As the enterprise grows, the intersection of sourcing and operations becomes a practical discipline. Operators increasingly depend on accessible market intelligence and supplier transparency to inform decisions about price points, inventory levels, and service windows. For instance, a truck that knows its most profitable hours and routes can calibrate its ingredient purchases to reflect demand variability, thereby reducing waste and evoking a sense of reliability among regulars. The street-food economy therefore rewards a holistic perspective: one that considers the entire value chain from the vehicle or build to the final bite, and that treats every link as an opportunity for improvement. In this sense, the taco truck becomes a microcosm of small-business agility, where competing on taste means competing on efficiency, reliability, and community integration.

Finally, a note on practical storytelling and best practices for ongoing success. The most robust operators keep a long, disciplined view of the business while maintaining the nimbleness needed for day-to-day operations. They maintain detailed supplier records, track maintenance and inspection results, and keep a close eye on regulatory changes that can affect food safety, ventilation, and electrical standards. They design their menus with a core set of staple items that travel well and a rotating feature that can be introduced quickly in response to local markets or events. They invest in staff training that emphasizes not only technique but also safety, cleanliness, and customer engagement. They cultivate habits that make the operation look effortless on the street, even though the practice behind the scenes is complex and precise. The result is a taco that carries authenticity, a kitchen that travels with confidence, and a business that can scale without sacrificing the very qualities that drew customers in the first place. For operators who want to go beyond a one-off success, the secret lies in treating sourcing, pricing, and operations not as separate tasks but as interlocking disciplines that reinforce one another with every service.

For readers who want to explore related ideas about sustainable practices and scalable mobile food operations, see the discussion on sustainable practices for mobile trucks. That resource provides additional context on how to balance cost, waste, and energy use while maintaining high standards for food safety and guest experience. sustainable-practices-mobile-trucks.

A final pointer to industry-wide perspectives on equipment standards and market dynamics can be found through the broader professional literature. For readers seeking a foundational external resource on market analysis, supplier directories, and technical specifications for mobile food equipment, including taco trucks sourced from international suppliers, refer to the Food Service Equipment platform. This external reference offers updated insights into equipment standards, compliance, and procurement considerations for operators navigating a rapidly evolving street-food landscape. https://www.foodserviceequipment.com/

Behind the Window: Safety, Regulation, and Cultural Craft in Taco Truck Style Tacos

Dawn light spills over a busy street where a compact kitchen on wheels sits with its hood raised like a patient in a hospital exam room. The griddle hums, the fryer sighs, and the scent of corn, sizzling fat, and bright cilantro cuts through the morning air. For many cooks, this is more than a job; it is a daily ritual of craft, speed, and hospitality. Yet within this ritual, there is a system: a framework of safety, regulation, and culture that shapes what arrives at a customer’s plate as much as the masa that becomes the tortilla. Taco truck style tacos emerge from a combination of intimate technique and public trust. They are the same simple, hand-assembled tortillas and protein-forward fillings that give street food its character, but they are performed in a compact, moving space where every action must be deliberate and audibly compliant with rules that ensure the community can safely share in the experience.

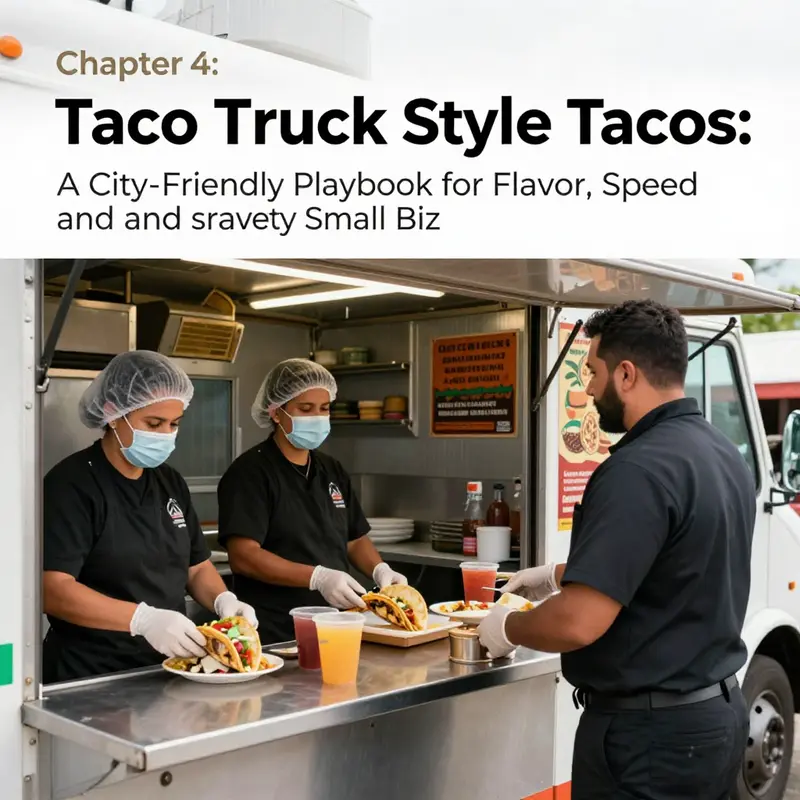

Food safety is the first and most visible layer of that system. The regulations that govern mobile food service are designed not to dampen flavor but to protect it from becoming a vector for illness. In many jurisdictions, a vendor must secure permits to operate and pass regular inspections that focus on temperature control, cross-contamination prevention, and waste disposal. The rules are not abstract. They translate into daily practices: hot foods kept hot, cold foods kept cold, clean hands and clean surfaces, and a clean path from raw ingredients to finished taco. For a taco cook, this is not mere bureaucracy; it is a promise that every bite maintains the integrity of the ingredients and the trust of the customer. The cooking equipment itself becomes a focal point of safety. Griddles and fryers, while essential for searing carne asada, salsa-coated shrimp, or crispy suadero bites, require routine cleaning, calibration, and inspection. A buildup of grease or a neglected flame can escalate into a fire hazard or create microbial growth that undermines flavor and safety. In the mobile kitchen, where space is a premium and heat is constant, a disciplined cleaning schedule is as essential as the spice blend.

The regulatory conversation does not stop at fire codes or temperature logs. It extends to the spatial realities of a truck that must park where customers gather, often near sidewalks, markets, or busy intersections. Jurisdictions commonly address how close a truck can park to restrooms, how available potable water must be, and how waste is stored and disposed of. These details matter because they influence not only food safety but also the customer experience. A truck with a reliable water source and a well-managed waste system communicates professionalism and safety. It reduces the risk of unsanitary practices that can occur when a vendor improvises. It also minimizes the chance that a bustling service window collides with a health officer’s need for a clear, accessible space to inspect, measure, and verify procedures. The process becomes a choreography: a dance of permits, inspections, daily checks, and a mobile operation that must remain transparent to the community and compliant with the letter of the law.

Beyond the mechanics of compliance lies a more nuanced dimension: how regulation intersects with culture. Taco trucks sit at the crossroads of tradition and mobility. In cities with large Latino populations, these mobile kitchens are not only places to eat; they are social hubs, sites of family pride, and expressions of regional culinary identities that travel, adapt, and sometimes blend. That cultural dimension is both reason for celebration and a call to balance. Excessively restrictive rules can threaten the viability of small, often family-run operations that sustain neighborhood economies and maintain the authenticity that draws people to a truck. Yet lax standards without enforceable safety measures can erode public confidence and undermine the very intimacy these trucks cultivate. The result is a push toward regulatory frameworks that safeguard health while recognizing the value of informal food cultures. Some municipalities now designate specific corridors or event zones for food trucks, providing predictable vending opportunities while preserving neighborhoods and public spaces. This approach acknowledges that street food is more than a commodity; it is a communal practice that helps define city life.

From a chef’s perspective, the regulatory landscape shapes the operational philosophy of the kitchen on wheels. It informs how the workflow is arranged, how ingredients are sourced, and how information is recorded. The best operators treat rules not as obstacles but as performance standards. They build accountability into the routine with simple, repeatable practices that support taste as well as safety. A responsible crew might, for example, maintain separate prep zones to minimize cross-contamination, keep a visible color-coded system for tools and boards, and document temperatures and cleaning times in a logbook that travels with the truck. This kind of discipline does not diminish the art of taco making; it preserves it by removing ambiguity about how ingredients are handled, stored, and cooked from start to finish. When a customer orders a simple taco al pastor, the sequence should feel effortless, but every action underneath—the thawing, the marinating, the marigold of onions frying lightly to release aroma—has been executed within a framework that prioritizes safety and consistency as much as taste.

Cultural context also invites reflections on how the community experiences the truck. The flavor of a sauce, the brightness of a salsa, and the texture of a tortilla carry memory and identity. The public health conversation, then, becomes a shared responsibility: vendors, regulators, and customers participate in a system of mutual respect. Customers expect clean surroundings, visible hygiene practices, and transparent information about ingredients. They also want to see the human story behind the food—the family recipe, the regional influence, the way a chef handles spicy peppers or a delicate guacamole. In this light, regulatory measures are not a cold framework but a scaffolding that allows cultural expression to flourish within safe boundaries. When a city supports vendors through safe parking design, accessible potable water, and predictable permit processes, it empowers culinary storytellers to bring regionally distinct flavors to street corners without endangering health or undermining community trust.

Effective communication is a subtle but crucial thread in this tapestry. Bilingual signage, clear labeling of ingredients, and transparent sourcing practices help bridge cultural expectations with regulatory requirements. For customers who come to a truck with a long-standing family recipe, knowing that the meat was sourced with care, that cross-contact with allergens is minimized, and that utensils and cutting boards are cleaned on schedule can deepen confidence and enjoyment. For operators, transparent communication is a tool to build loyalty in an increasingly competitive landscape. When a menu describes a marinade, a salsa, or a heat level with honesty and warmth, it sets the tone for a dining experience that respects tradition while inviting new audiences to explore.

The practical implications of this blend of safety, regulation, and culture show up in everyday decisions. It begins with how a truck is designed—the placement of a thermometer display, the proximity of raw and cooked ingredients, and the route from dishwashing station to handwashing sink. It continues in how the day unfolds: checking that ice is sourced from a clean, protected supply, ensuring that the hot line stays above a safe threshold, and maintaining a never-empty handwashing station that customers can observe. It extends to how the menu evolves: offering a few well-executed proteins, sauces, and toppings that travel well and stay consistent when the truck moves from one crowded block to another. In this context, the assembly-line vibe that characterizes taco truck service becomes a model of efficiency rather than a risk. A well-tuned workflow allows for quick service without sacrificing cleanliness or safety, a balance that is essential to sustaining both flavor and public trust.

There is also a broader, more aspirational layer to consider: the role of sustainable and equitable practices in mobile food operations. The culture surrounding taco trucks increasingly recognizes that safety is inseparable from the stewardship of resources. Responsible waste management, proper grease containment, and efficient water use all contribute to a neighborhood’s well-being. A truck that plans for waste disposal and grease handling reduces the risk of neighborhood contamination and aligns with a broader social duty to minimize environmental impact. In many cases, this aligns with community-oriented values, as trucks often participate in local events, fundraisers, or neighborhood revivals. When a vendor demonstrates both culinary skill and civic responsibility, the truck becomes not only a source of meals but a trusted neighbor in the block-long, sunlit street ecosystem.

For operators seeking to weave these threads into practice, the emphasis should be on habits, not miracles. Build a routine that makes safety and sanitation a visible, everyday part of service. Develop a simple, repeatable cleaning schedule that covers every surface, tool, and piece of equipment at the end of each shift. Keep records shrewdly but accessibly, so that a health inspector, a partner, or a curious customer can see the dedication to standards. Train staff to think of food safety as part of hospitality, not a separate, punitive obligation. When a cook reminds a teammate to wash hands before handling tortillas or to label a container with a date and a product name, it is a moment of culture meeting regulation—a small act that sustains the larger mission of sharing tradition with warmth, flavor, and safety.

In the broader arc of this article, safety, regulation, and culture are not three separate domains but a single, living system. The taco truck is a microcosm of urban food economics, balancing access, cost, and quality while navigating the rules that govern public spaces. The best practitioners view this as an opportunity: to design a kitchen that travels well, to cultivate a reputation built on reliability as well as taste, and to anchor a business in a community that values both tradition and safety. The goal is not to mandate conformity for its own sake but to preserve the freedom to innovate within boundaries that protect the consumer and honor the cultural significance of the cuisine. In doing so, the craft of taco truck style tacos remains vibrant and resilient, capable of telling regional stories through the universal language of a warm tortilla, a bright salsa, and a shared meal watched by a street that never truly sleeps.

For readers who want to connect practical practices with a broader framework, consider exploring sustainable practices for mobile food trucks, a holistic approach that frames everyday operations as part of a larger commitment to health, efficiency, and community wellbeing. sustainable practices for mobile food trucks.

External resources can illuminate how laws shape the everyday realities of street food. For a comprehensive overview of safety standards, permitting, and compliance frameworks in food truck operations, refer to industry analyses and regulatory white papers that discuss how cities balance public health with economic opportunity. The following external resource provides one authoritative perspective on regulating mobile food service: https://aws.amazon.com/whitepapers/regulating-food-trucks/ .

The window of a taco truck is both a literal window and a conceptual doorway. It invites you to imagine a scene where technique, safety, policy, and culture converge in a single, flavorful moment. The best operators make that moment feel effortless for customers while staying true to the rules that protect them. In doing so, they preserve not only the integrity of a dish but the integrity of a street-food tradition that continues to feed, teach, and connect communities across neighborhoods and borders.

Final thoughts

Mastering taco truck style tacos means blending traditional technique with the realities of mobility. Start with a compact, well-planned kitchen layout, a focused core menu that travels well, and pricing that reflects speed, quality, and demand. Safety and regulatory awareness aren’t obstacles; they’re the foundation that earns trust and repeat customers in any urban setting. When you combine precise execution, reliable sourcing, clear cost control, and respect for the communities you serve, you create an authentic, scalable mobile taco operation that can adapt to markets near and far while keeping flavor front and center.