If you’re eyeing a taco truck or a mobile kitchen, the big question is simple: how much for taco truck catering? Yet the answer isn’t one number. It’s a spectrum defined by size, equipment, new versus used status, and where you’ll operate. For urban commuters, downtown dwellers, outdoor enthusiasts, and bold small-business newcomers, the sticker price also reflects how you’ll serve, brand, and grow. This guide breaks the topic into five focused chapters that build a complete financial picture. Chapter 1 lays out price ranges and baseline cost factors so you can anchor your expectations. Chapter 2 explains how equipment configurations drive costs without sacrificing service quality. Chapter 3 compares new versus used trailers and what financing might look like in practice. Chapter 4 highlights ongoing costs, permits, and compliance that turn a trailer into a legitimate business. Chapter 5 reveals how geography and market demand shift pricing and profitability. By the end, you’ll have a practical framework to estimate startup costs, plan cash flow, and negotiate confidently with suppliers. Whether you’re a freelancer chasing side gigs, a small team launching a first-time pickup, or an outdoor enthusiast aiming to monetize events, this holistic view of taco truck pricing keeps the focus on real-world decisions and outcomes.

Behind the Price Tag: Decoding Price Ranges and Baseline Costs for Taco Truck Catering

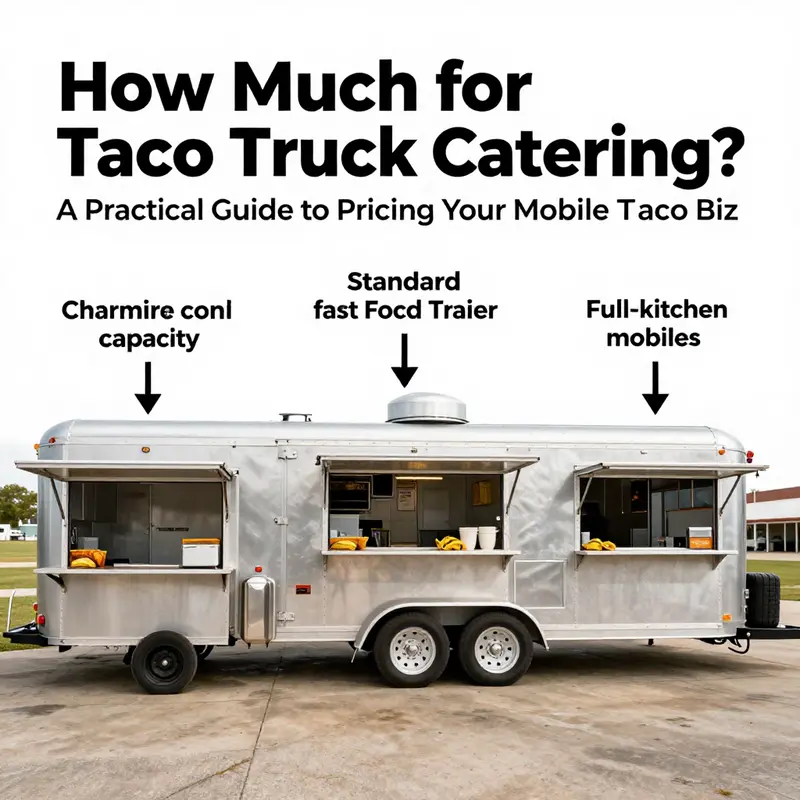

Pricing for taco truck catering sits at a crossroads of form, function, and ambition. When aspiring operators ask, how much for taco truck catering, they are really asking how to translate a menu into a mobile kitchen that can perform reliably in different spaces, at different events, with different volumes. The answer is rarely a single number; it is a spectrum defined by three broad paths, each driven by what you want your kitchen on wheels to do, how turnkey you need it to be, and how you plan to grow. On one end you find compact, basic carts designed to get you to first service quickly, often priced in the low thousands when bought in bulk. In the middle, standard fast‑food trailers offer more interior space and a more complete cooking flow, typically reaching into mid five‑figures for a single unit. On the far end, a full kitchen mobile trailer promises a restaurant‑quality workflow on wheels, with scale options that can push costs higher still. This range reflects not just the chassis, but the heart of the operation: the equipment inside, the safety and certification standards, and the level of support you’ll receive after delivery. Understanding these levers helps you negotiate confidently and design a setup that matches both your cuisine and your schedule.

The price picture can look inconsistent at first glance because different sources quote different baselines and inclusions. Taken together, though, the numbers sketch a coherent frame. A basic taco food cart sold in bulk can start quite low, with prices kicking off in the vicinity of a few thousand dollars per unit when you order seven or more. The logic is straightforward: mass production drives per‑unit costs down, and buyers who purchase in quantity often secure the most favorable terms. Conversely, single-unit purchases, without the leverage of bulk orders, tend to sit higher in the pricing spectrum. A standard, standalone fast‑food trailer designed to operate as a self-contained unit commonly lands in the five- to eight-thousand-dollar range, depending on the specific configuration and the equipment included. It is easy to see why many new entrants gravitate toward a one‑unit purchase with a modest initial menu and a tight service footprint before expanding. Yet there is also a middle path—the full kitchen mobile trailer—that can be surprisingly competitive in price if you choose a configuration that focuses on essential capacity rather than every imaginable amenity. In some cases, a compact full‑kitchen solution can start in the neighborhood of a few thousand dollars per piece, though the total investment will climb quickly as you add appliances, ventilation, and safety systems to handle a more ambitious menu.

Delving into what those price points represent helps demystify the industry jargon. Base offers for new trailers or trucks often include the core build quality and durability. Expect stainless steel worktables, non‑slip flooring, a built-in electrical system with lighting and universal sockets, and a sturdy composite‑board and steel construction as standard components. These basics are the scaffolding that keeps a mobile kitchen functioning under daily use, and they form the foundation on which all other features are layered. The exact inclusions, however, vary by supplier and by whether the unit is configured as a simple prep cart or a more complex cooking station. When a vendor markets a turnkey setup with multiple appliances, integrated refrigeration, and a ventilation system, the price will rise in proportion to the added reliability, efficiency, and safety. The key point is not just the number of appliances, but how well the layout supports the cooking sequence, how safely heat is managed, and how easily a crew can move from prep to service without tripping over hoses or pans.

Size and design are the next critical determinants. A commonly cited baseline for many mobile kitchen offerings is roughly four meters in length, two meters in depth, and about two and a third meters tall. That footprint balances urban maneuverability with interior space for working surfaces, a compact prep zone, and a functional exhaust or ventilation workflow. If you require a larger footprint or an unusual shape to accommodate a distinctive workflow, more interior width, or additional storage, the price increment can be substantial. The interior layout is not a cosmetic choice; it directly affects how many team members can work efficiently at once, how quickly orders move, and how easy it is to keep the workspace clean and safe during a busy shift. In other words, a small, tightly planned interior can deliver high throughput at a lower initial cost than a larger, more ambitious build that promises greater throughput but demands more upfront investment.

Customization is where price tangibly reflects strategic choices. Exterior color and branding, interior layout modifications, and the precise placement of equipment all contribute to the final figure. A plain exterior with minimal branding will always be cheaper than a highly branded shell wrapped in attention-grabbing graphics. Inside, the decision to add more refrigeration, a larger grill line, or a more sophisticated exhaust system each adds to the price, but those investments can yield meaningful gains in service speed, menu flexibility, and food safety. The pattern is logical: if your concept hinges on consistent, quick service and a broad menu, you will likely invest more in a layout that minimizes motion and maximizes stability for the staff. If your concept begins with a lean menu and a tight schedule of events, a simpler interior and fewer customization demands can keep your upfront costs in check while you validate demand.

Equipment integration is the third decisive axis. Some buyers come with a fixed equipment plan—grills, fryers, ovens, refrigerators, and a ventilation arrangement—while others rely on a more open platform that invites modular additions as the business evolves. Each additional appliance or feature adds weight, power demand, and installation complexity, all of which influence the quoting and long‑term maintenance. The upshot is that the same chassis could represent a lean, single‑purpose cart or a robust, multi‑appliance mobile kitchen, with a wide delta in price between the two. The takeaway is practical: define your menu and your prep flow first, then align your equipment selections with the space you can devote to the trailer and the electrical capacity you can responsibly support. This alignment minimizes the risk of overinvesting in capabilities you won’t use every shift and underinvesting in the basics you need for consistent service.

Safety, standards, and shipping are the final layers that often determine the final price. Compliance with safety standards—things like electrical safety, fire protection, and food hygiene requirements—can add to the initial quote, but they also unlock access to official permits, insurance, and customer trust. Shipping and packaging logistics also affect the final cost. Some buyers negotiate terms that include protective packaging, direct-to-site delivery, and on‑site assembly assistance, while others accept standard freight with local installation. The geographic origin of the manufacturer matters because price pressure in some regions is offset by longer shipping times and potential import hurdles. In practice, many buyers choose a regional supplier to shorten lead times and simplify maintenance, even if the upfront cost is slightly higher than a distant alternative. The practical effect is that the total ownership cost is a function of the initial build price plus ongoing costs for maintenance, insurance, fuel or power, and routine replacements.

Startup budgeting for a taco business is not only about the trailer. Permits, insurance, initial inventory, and a small crew to manage early events should be included from day one. A conservative projection sets aside a cushion for unexpected repairs, supplier delays, or equipment upgrades that become necessary as you grow. If you are starting with a lean unit, plan for flexible staffing and a strategy for building a steady number of events per month to establish cash flow. If you pursue a mid‑range or premium kitchen on wheels, your budget should reflect not only the enhanced capability but the requirement for a reliable maintenance plan, established supplier relationships, and a marketing approach that makes the most of your branding. In either case, the total cost of ownership is more informative than the sticker price alone because it captures what you will actually invest to keep the trailer, the crew, and the menu performing at peak levels.

As you navigate this landscape, keep in mind that the numbers tell only part of the story. The best way to translate cost into a solid business plan is to pair price ranges with a clear vision of your service model, event cadence, and growth trajectory. A lean, reliable platform can enable you to test a concept with lower risk, then scale as demand proves itself. A more ambitious setup, while requiring larger upfront investments, can unlock a broader menu, faster service, and a stronger brand presence if you anticipate regular, high-volume opportunities. If you want a practical route to evaluating equipment decisions, you can explore a resource that emphasizes choosing equipment wisely for a mobile kitchen. It offers a framework for aligning your hardware with your business model: Choose food-truck equipment wisely.

For readers seeking an external benchmark, consider browsing an external marketplace listing that aggregates mobile food cart and taco catering pricing and specifications to ground your expectations in real-world quotes. This external reference provides context for how similar configurations are priced across suppliers and markets. External resource: https://www.alibaba.com/product-detail/Fast-Food-Carts-Taco-Catering-Cart-Vending1600584162436?spm=a2700.100112.1000795.100&src=alibabasearch&search=true&scm=1007.10135.1000795.0&sourceType=1&searchText=taco%20truck%20catering

From Chassis to Chimneys: Decoding Equipment Configurations and the Real Cost of a Taco Truck Catering Setup

The path from an idea to a working taco truck begins with a single, but critically influential choice: how the equipment is configured. In the world of mobile catering, the trailer or cart is not just a shell; it is the engine of your operation. The money you invest in equipment determines not only your upfront budget but also how you cook, how fast you serve, and how consistently you can deliver on a menu that attracts repeat customers. When you survey the landscape of pricing, you quickly see that the cost of taco truck catering is not a single number. It’s a layered sum, where the base trailer price often represents only a starting point, and every practical decision about gear adds lines to the ledger. The most honest way to approach this is to trace the journey from a basic chassis to a fully functional kitchen on wheels, and then to translate those decisions into a cost that aligns with your business goals and the realities of your local market.

Even at a high level, the base figures matter. A basic mobile food trailer, in the current market, starts at prices that are sometimes in the mid four-figures for several units, with bulk or volume discounts. For example, a base price around US$4,100 for a small batch of units can include the chassis and body, plus a composite board, a steel structure, a 220V/110V electrical system, and a relatively compact footprint of roughly 4 meters by 2 meters by 2.35 meters. This is not a full kitchen, but it is the critical starting point that makes the rest of the setup possible. It’s the platform that carries your future equipment and your compliance obligations. Crucially, that base figure reflects the trailer’s skeleton—its frame, walls, basic electrical loop, and the generic kitchen area—rather than a fully equipped operational kitchen. When you step beyond the shell, the total cost starts to rise quickly, and for good reason: quality, safety, and efficiency hinge on the gear you choose to install.

The heart of the cost discussion is the decision about what to install inside that shell. A taco operation’s essential equipment spans several categories: cooking surfaces, wet and dry storage, refrigeration, water systems, ventilation, and the point-of-sale and branding that turn a mobile kitchen into a business. Grills and griddles are the workhorses of a taco menu. Their type—gas or electric—along with their capacity, helps define both upfront price and ongoing energy use. Gas-fired equipment tends to require robust ventilation and gas lines, but can offer rapid heat and familiar cooking dynamics for high-volume services. Electric models, while potentially easier to install with fewer ventilation requirements, can demand higher electrical capacity and careful power management. Either path affects how many units you need, the power infrastructure you must install, and the daily fuel or electricity costs that nibble away at profit margins.

Deep fryers, often essential for tortilla preparation and for side offerings like fries, introduce another layer of cost and complexity. They require a steady supply of oil, regular changes, and filtration systems to keep flavors clean and costs predictable. The space they occupy is non-trivial, and their maintenance cycle adds ongoing expense, not just a one-off purchase price. The more robust the fryer, the more tortillas you can fry per hour, but you must balance that against oil management, filtration needs, and the extra weight inside the trailer.

Refrigeration is another driver of cost and capability. A taco truck typically needs refrigerated storage for meat, dairy, toppings, and prepared components. The size, efficiency, and number of units you install influence both upfront cost and daily energy usage. Efficient, properly insulated units can reduce running costs and keep ingredients safe, but they command higher purchase prices and may require sturdy mounting and vibration-proof installations. The water system and exhaust hood are not only about convenience and safety; they are often dictated by local health codes and fire regulations. A reliable water supply and an exhaust system capable of handling the heat and steam generated by grills and fryers are essential. The choice of hood size, duct routing, and filtration can push initial installation costs higher, but these elements protect you from compliance issues that can stall or shut down a business.

Then there is the technology layer—the POS terminal, menu boards, and branding elements that turn a trailer into a brand on wheels. A robust POS system improves order accuracy, speeds service, and delivers data that can steer menu decisions and promotions. Yet, every added technological feature carries a price, not only in the hardware itself but in the installation, cabling, and ongoing maintenance. Custom branding, meanwhile, translates to a more attractive customer experience and higher perceived value, but it is another line item that tightens the difference between a lean setup and a premium kitchen-on-wheels.

Taken together, the math of cost becomes a narrative of priorities. A lean, practical configuration may emphasize a compact grill or griddle, minimal fry capacity, and a small reach-in or under-counter fridge. This keeps upfront costs manageable and streamlines operation, albeit with a narrower menu and slower service at peak times. A broader, more ambitious configuration expands cooking capacity, adds more refrigeration, increases cold storage and prep space, and incorporates a more elaborate ventilation and drainage system. The initial sticker price climbs, but the payoff can come in the form of higher sales per hour, the ability to offer a wider array of toppings or specialty items, and greater resilience during busy events. In the span between these extremes lies a continuum of options that reflect the operator’s goals, the target events, and the regional price environment.

The financial reality that anchors these choices is straightforward: fully equipped taco trucks cost more than a bare trailer, but the additional investment unlocks capabilities that more than offset the expense when executed correctly. Industry perspectives suggest that a fully equipped taco truck often falls in the broad range of US$50,000 to over US$100,000, depending on the quality, capacity, and the scope of the equipment package. This broader figure captures not just the kitchen gear but the complete system: water and waste, exhaust and ventilation, electrical capacity, connectivity, and the branding ecosystem that makes the truck a practical business vehicle rather than a simple shell. The takeaway is clear: the upfront outlay to realize a fully functional, compliant, and efficient taco truck is substantial, but the long-term payoff hinges on how well the configuration aligns with your menu complexity, event profile, and operating discipline.

With that in mind, it’s helpful to think of equipment selection as a calibration exercise. Each choice should be evaluated against three core questions: What is the minimum viable equipment set that allows me to run a consistent, safe operation and deliver on my menu? How will this configuration scale with volume across peak days, festivals, and catering gigs? What are the ongoing costs—oil, gas, electricity, maintenance, and replacement parts—that will determine my profitability over time? The process is iterative. You start with a baseline based on your anticipated daily volume and the menu you intend to offer. You then layer in optional elements that expand capability and service speed, and you prune anything that does not contribute to a clear, measurable return.

To support this decision-making, many operators turn to practical resources that outline equipment specifications and performance expectations. For instance, a concise procurement guide emphasizes how to balance temperature control, space constraints, and energy efficiency while staying within budget. The conversation then shifts from “What can I fit in here?” to “What will reliably deliver at the events I care about, with a predictable cost profile?” This is where the interplay between upfront investment and operating costs becomes most visible. A lean, efficient setup might optimize labor and service speed, while a more expansive configuration can unlock a broader menu and higher ticket averages. Neither path is inherently superior; they are different routes to the same objective: a profitable, scalable mobile food business.

For operators navigating these trade-offs, it can be invaluable to see concrete guidance on equipment selection and prioritization. For practical guidance on selecting equipment, see Choose food truck equipment wisely.

As you finalize a plan, remember that the numbers are not merely about the price tags you see upfront. They reflect a chain of decisions about space, energy use, maintenance, and speed of service. A well-chosen configuration helps you keep turnover high during busy periods, reduces the wear and tear on staff and equipment, and keeps operating costs predictable enough to forecast profitability across events. The ultimate metric is not the lowest initial price but the lowest total cost of ownership over the first year of operation and beyond. A simple, rule-of-thumb approach is to compare the total cost of ownership of several configurations over a typical calendar of events in your target market. If one option offers a modest premium in upfront cost but materially lowers daily operating expenses or increases throughput, that difference can translate into faster break-even and a stronger financial position in the long run.

In practice, the journey from base trailer to fully functional taco kitchen is a narrative of scale and discipline. It requires a clear vision of menu scope, a realistic assessment of event opportunities, and a pragmatic eye for long-term maintenance and energy management. The range of possibilities is wide, but by anchoring decisions in the realities of space, weight, heat, and safety, you can navigate toward a configuration that fits your budget while delivering the performance that customers expect. The numbers—from base chassis pricing through to the tens of thousands tied to full kitchen outfitting—are not arbitrary. They are a roadmap to a business that can serve great tacos reliably, at scale, and with a profitability that supports growth. For those who want a structured approach to weighing gear against price, the guidance is to start with essential gear, map its footprint and power needs, and then layer in capabilities that deliver the most significant returns on the line.

External resource for further reading: https://www.foodtrucksupply.com/blog/food-truck-equipment-guide/

From Fresh Start to Secondhand Steady: Navigating New, Used, and Financing Pathways for Taco Truck Catering

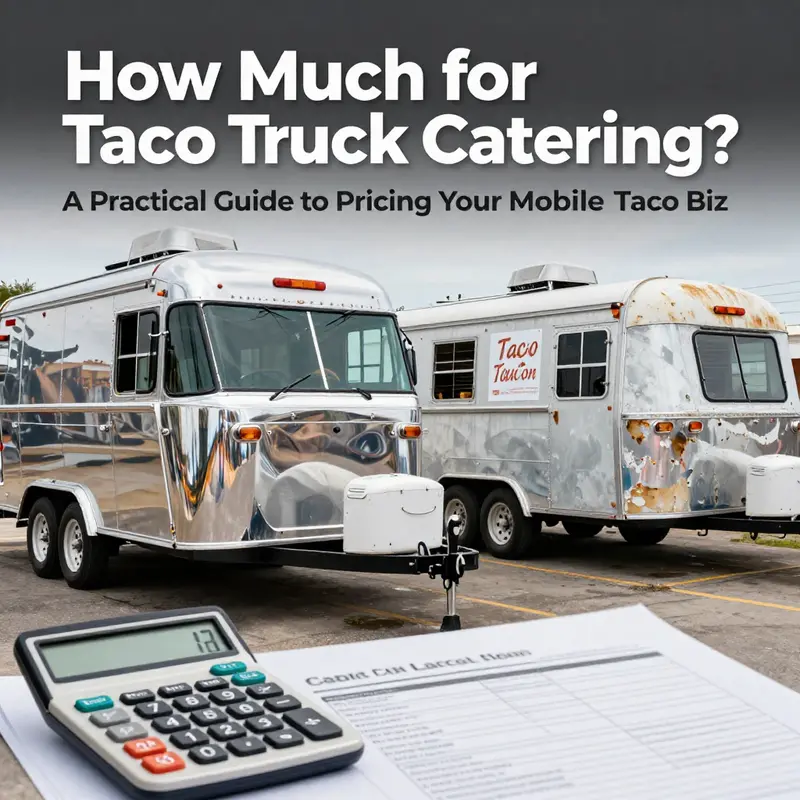

Choosing how to equip your taco catering operation is more than a single price tag. It is a decision that defines how quickly you can launch, how reliably you can operate, and how resilient you will be as you grow. The initial investment hinges on a simple but powerful contrast: do you pursue a brand-new trailer with all the latest design refinements, or do you start with a well-kept used rig and build from there? The answer is not simply about saving money upfront; it is about balancing risk, maintenance, and cash flow with your aspirations for menu breadth, branding, and geographic reach. In this chapter we explore the spectrum of options and the financing pathways that turn a vague dream into a road-ready kitchen on wheels. The goal is not to prescribe a single route, but to illuminate how the cost dynamics unfold and how to select a path that fits your market, your skill, and your growth plan.

New trailers carry a distinct appeal. They promise longevity, predictable performance, and a canvas you can tailor to your menu and brand from the outset. A brand-new taco trailer often comes with a clean slate: modern layouts designed for efficient cooking, reliable equipment, and warranties that cushion the first years of operation. While the exact sticker price varies with size, equipment level, and customization, it is common to see fully outfitted new units positioned in a broad band that starts higher than entry-level used rigs and can climb substantially with premium configurations. Realistic ranges for a new, completely equipped mobile kitchen tend to be in the neighborhood of $20,000 to $40,000 or more, depending on the footprint, appliances, refrigeration capacity, exhaust systems, and power requirements. In some instances, buyers report lower quotes for minimal configurations, but those figures are the exceptions rather than the rule. The upside of this investment is clear: fewer immediate repairs, more consistent energy efficiency, standardized layouts that scale with your branding, and the peace of mind that comes with a warranty and a service network. If your plan is to deploy quickly in a few high-traffic markets and to grow through repeat events, a new trailer becomes a predictable anchor for your operations and your customer experience.

On the flip side, used trailers present a compelling pathway for entrepreneurs who are testing the waters or working within a tighter budget. The lower upfront cost can be a decisive factor for many first-time operators. Some listings do fall below the six-figure threshold, with prices that can dip under $13,500 when the unit is older or smaller, or when the sale reflects a strategic bargain to move inventory. Yet buyers should approach used trailers with careful due diligence. Worn components, outdated insulation, energy-inefficient appliances, or hidden structural concerns can translate into unplanned downtime and escalating maintenance bills. The absence of a warranty adds another layer of risk. A thorough inspection—ideally with a third-party trailer inspector who can verify mechanical integrity, electrical systems, refrigeration performance, and structural soundness—can mitigate most surprises. If a used trailer passes those checks, it can provide a cost-effective springboard that allows you to allocate more capital to branding, menu development, and initial working capital. The trade-off is not merely the current price but the expected lifetime, reliability, and the scope of potential repairs.

Beyond the sticker price, both new and used trailers require thoughtful budgeting for what comes next. The base price typically covers the chassis and a basic kitchen setup, but most operators will add or upgrade equipment to support their specific menu—taco grills, steam boxes, fryers, refrigeration, cold prep spaces, hand sinks, and a robust exhaust system are common components that influence total cost. Then there are branding and permitting expenses, which can include exterior wraps, signage, menu boards, and compliance-related updates to meet local health and safety codes. Insurance and licensing add recurring annual costs that must be incorporated into cash-flow projections. The trend toward mobile food service also tends to raise costs in the areas of electricity and gas supply, depending on whether you use propane, natural gas, or electricity from portable generators or shore power. These ongoing costs ebb and flow with the volume you expect to serve and the markets you target.

Financing these assets opens another important axis of consideration. Because the price of a trailer represents a substantial capital outlay, many prospective operators turn to financing mechanisms that spread the burden over a multi-year horizon. Traditional small-business loans from banks or credit unions are a common route, often covering a large portion of the purchase with terms that stretch from three to seven years. The actual loan-to-value ratio and the interest rate hinge on your credit history, business plan, and collateral. Equipment financing, which is designed specifically for vehicles and trailers, allows you to reserve the trailer as collateral while paying over time. Lease-to-own arrangements can also be attractive for operators who want to preserve upfront working capital or who anticipate rapid expansion. These programs may offer flexible payment schedules or options to upgrade equipment as the business grows. A cautious approach is to compare total cost of ownership across these options, including interest, fees, maintenance expectations, and the potential for warranty extensions or service packages that are tied to financing terms.

Within financing conversations, it is worth noting the practical realities that often accompany international or multi-supplier purchases. Some buyers explore secure payment protections and platform guarantees when dealing with non-local sources. While these protections can help reduce risk, they also require careful scrutiny of terms, delivery timelines, and the reliability of post-sale service. Regardless of the source, a robust due-diligence process remains essential. Request references, verify equipment histories if buying used, and, if possible, arrange a test run or a condition report before signing. A reputable lender will want to see a clear plan for how the trailer will be used, the expected event schedule, and a realistic projection of revenue versus operating costs. As you map your financing mix, it can be helpful to build a conservative forecast that accounts for slow seasons, price competition, and the cost of obtaining permits and insurance in your target markets.

For operators who want a grounded middle path, a blended approach often makes sense. Consider starting with a used trailer that has been repurposed and upgraded to meet basic branding and health standards, paired with a modest line of essential equipment and a plan to phase in replacements or upgrades as revenue grows. This strategy can reduce risk while keeping the door open to a future upgrade to a fully customized new unit. It is crucial to document all anticipated upgrades with a clear budget and a realistic schedule so that cash flow remains steady and business momentum is not interrupted by unplanned investments.

As you reflect on the path that best suits your plan, remember a practical tip: the right trailer choice should align with your menu, your target audience, and your event calendar. Brand clarity matters as much as kitchen efficiency. A cohesive look, a reliable cooking workflow, and a dependable service pace all translate into repeat customers and word-of-mouth growth. If you are navigating multiple options, keep your decision anchored in a well-structured financial model that captures the long-term implications of either route. In this regard, the choice is less about chasing the lowest price and more about balancing durability, operating efficiency, and growth potential over the first 12 to 24 months of operation. The emphasis should be on sustainability: how soon can you break even, how resilient will your setup be in peak season, and how sharply can you scale your business once events begin to multiply.

To help keep this decision grounded, consider a practical note on equipment selection as you plan your setup. When you are weighing different trailers, the path toward a smart choice often hinges on equipment versatility and ease of upgrades. The kitchen layout should support your menu with room to add or swap components as you expand. Look for chassis that accommodate a safe and smooth workflow for cooks and service staff, with a design that minimizes heat and odor dissipation in the open-air environment. A well-planned ventilation system, appropriate electrical load capacity, and efficient cold storage are not luxuries; they are prerequisites that keep your operation smooth during busy shifts and travel days. In this light, the decision to pursue new or used becomes a strategic hinge rather than a one-off purchase.

As you weigh the path forward, you can also think about how to connect with broader resources that illuminate market realities and financing options. For a practical perspective on pricing and financing options, you can refer to a comprehensive pricing guide that aggregates current market offerings and financing structures. This can help you calibrate expectations and avoid overpaying for a trailer that does not match your operational needs. For readers who want to see a structured snapshot of market pricing, the external resource mentioned below provides a broader context that complements the insights in this chapter. Additionally, as you plan equipment choices, consider the practical guidance offered on choosing food truck equipment wisely. Choose food truck equipment wisely.

In short, the decision between new and used, and the choice of financing path, folds into a broader strategy for your taco catering business. A fresh unit can offer peace of mind and branding advantages, but it comes at a premium and a longer ROI horizon. A used trailer can accelerate market entry and preserve cash, yet it requires meticulous due diligence and a readiness to invest in renovations. Financing changes the arithmetic, transforming a large upfront cost into a predictable operating expense that aligns with sales tempo and growth milestones. The right combination depends on your market, your appetite for risk, and your strategic plan for service quality, brand presence, and geographic reach. With thoughtful analysis and careful planning, the initial investment becomes the launchpad for a sustainable, scalable taco-truck catering operation.

External resource: For a broader market snapshot on pricing and financing options, see the pricing guide from FoodTrucks.com. FoodTrucks.com Pricing Guide

From Carts to Contracts: The Real Cost of Taco Truck Catering and How to Navigate It

Choosing taco truck catering as a business model means more than picking a menu; it is a careful calculus of upfront capital, ongoing operating costs, and the regulatory path that can either accelerate growth or tighten the margins. The financial dynamics of a mobile food operation sit between the fixed costs of a brick-and-mortar restaurant and the variability of a seasonal pop-up. What looks affordable at first glance often reveals hidden obligations once permits, compliance, and maintenance enter the picture. For anyone mapping out a taco truck venture, the numbers behind the scenes matter as much as the salsa on the shell, because small differences in cost structure can compound into large differences in profitability over time.

Upfront capital and setup costs anchor the entire venture. The vehicle and the kitchen it carries are the foundation, and they come in a spectrum of choices. A used mobile cooking van, with its own wear and tear, typically lands in a broad range around fifty thousand to one hundred thousand dollars. A custom-built mobile unit, designed to match a specific menu, equipment, and branding, can easily exceed two hundred thousand dollars. These figures reflect more than just a shell; they include the quality of the ventilation, the reliability of the wiring, the layout efficiency, and the capacity to handle peak service periods without breaking down. The initial investment is a major hurdle, but it also sets the stage for long-term efficiency and service quality. In practice, many buyers start with a leaner setup and scale up as demand confirms the model. Early missteps—such as underestimating refrigeration needs or overloading a generator—can punish margins with expensive repairs and energy waste.

Even within the lower end of the market, there are compelling options worth understanding. Basic taco food carts, especially when purchased in bulk, can start at relatively modest price points—around one thousand six hundred eighty dollars per unit for seven or more units, with unit prices typically decreasing as order volume increases. This bulk pricing creates a tempting entry path for aspiring entrepreneurs who want to test a concept with a fleet of small, consistent-quality units. However, bulk pricing rarely translates into a long-term savings if the fleet size remains small, because the per-unit maintenance and logistics costs accrue with each unit on the road. For a single, standalone trailer or cart, the sticker price tends to be higher, reflecting the absence of the discount tier that bulk buyers enjoy. And while the market also features full kitchen mobile catering trailers that start at several thousand dollars per piece, that base figure often masks the true cost once you equip the unit with the necessary refrigeration, gas lines, exhaust systems, prep surfaces, and food-safety hardware required to operate legally in many jurisdictions.

These upfront figures set expectations, but they do not capture the total cost of ownership. A fleet that runs efficiently from day one benefits from careful planning around energy use and maintenance. The operating costs accumulate as soon as the wheels turn. Fuel is an obvious expense, and the per-mile cost can be higher for a mobile operation than for a stationary restaurant, given the extra driving required to reach multiple event venues and the downtime between shifts. Fuel efficiency matters, but so does maintenance. Mobile units endure stricter vibration, dust, and heat, all of which accelerate wear. Routine servicing—oil changes, brake inspections, generator tune-ups, and refrigeration checks—becomes a regular line item. Unexpected breakdowns can derail a schedule and damage a brand if late deliveries or cold-food spoilages occur. Insurance is another continuous cost: commercial auto coverage and general liability protection are typically non-negotiable, and premiums reflect the risk profile of a mobile operation that often parks in varied neighborhoods and navigates urban constraints.

Labor costs add another layer of complexity. A taco truck that operates at peak demand times may still need a crew for prep, cooking, service, and breakdown, plus a manager who coordinates routes, permits, and vendor relationships. Labor efficiency ties directly to the layout of the kitchen and the ability of staff to move between zones without stepping on each other’s toes. In some markets, seasonal demand drives a flexible staffing model, with part-time workers stepping in during festivals or weddings. The upside is greater service capacity and the potential to capture events that would overwhelm a fixed-location operation. The downside is the potential for wage volatility and the administrative burden of payroll, tax withholdings, and workers’ compensation costs. All of this matters because it directly curtails or expands margins, especially when demand shifts across the calendar.

Licensing and licensing-related costs form a recurring, sometimes opaque, component of the financial equation. In many regions, a commercial driver’s license or a comparable credential is required to operate a food truck legally. The credential adds to the entry barrier, signaling a baseline of competency and safety. Beyond licensing, the licensing and permitting landscape can be labyrinthine; a typical pipeline includes a business license, a food-service permit, and a vehicle inspection. There may be health department registrations, fire-safety compliance certificates, and waste-disposal permits. The costs are not purely initial; some jurisdictions levy recurring fees and annual renewals, while others impose periodic inspections that carry both time and financial costs. Jurisdictional variation matters, too. Some cities restrict where a truck can park or operate, either in busy downtown areas or near specific venues, and these restrictions can change with events calendars and policy shifts. The practical impact is a schedule that must be navigated with foresight. A truck that cannot reach its target audience due to parking limitations risks idle days and wasted fuel, eroding the return on investment.

Permitting, zoning, and ongoing regulatory compliance deserve close attention because they shape both feasibility and profitability. Health and safety regulations drive the design and operation of the kitchen. Trucks must meet sanitation standards, keep proper temperatures, and maintain documentation that inspectors can audit. The application process for permits often requires site plans, menu disclosures, and proof of staff training. Some locales impose recurring permit fees in addition to the initial approvals, creating a steady overhead that must be accounted for in pricing strategies. Operational restrictions further complicate planning. If a truck’s route is confined to certain hours or districts, a business may need to schedule events to align with those windows, sometimes sacrificing convenience for compliance. The practical effect is that regulatory complexity can delay startup timelines, add to overhead, and demand ongoing compliance monitoring to avoid penalties.

Pricing and value proposition sit at the heart of the business case for taco truck catering. In many markets, the published rate for taco truck catering runs roughly from fifteen to thirty dollars per person. This is a compelling figure when compared with traditional catering, which often ranges from twenty to eighty dollars per person depending on menu complexity and service style. The taco truck model competes on value, speed, and the ability to scale to large crowds without the overhead of a full-service kitchen. Yet delivering that value requires disciplined cost control. If fuel, insurance, and labor costs rise, margins tighten quickly unless ticket prices can be adjusted or volume increases to compensate. Equipment depreciation also enters the calculus. Even with a lower per-event price, the amortization of a high upfront investment can produce attractive margins when the unit operates at high utilization, is reliably maintained, and experiences consistent demand across a diverse event mix—including weddings, corporate functions, and community festivals.

The compliance risk landscape is real and consequential. Noncompliance with licensing, health, and parking rules can trigger fines, temporary or permanent shutdowns, and reputational damage. A damaged reputation can curb future bookings just as surely as a price increase can deter repeat clients. This is why many operators invest in a robust compliance system that tracks permits, schedules renewals, and trains staff on food safety and customer service. A proactive approach to regulatory readiness can become a differentiator, not just a shield against penalties. To help navigate these waters, many would-be operators consult established guides that map permits, licensing, and financial planning. For example, the U.S. Small Business Administration provides a comprehensive, up-to-date starting point for food truck ventures, including practical guidance for permits, licensing, and budgeting. It is wise to consult such resources early in the planning phase and periodically as the business grows.

For readers who are outfitting a truck, a practical starting point is to consider not only the equipment you need but how it fits into a compliant operating model. A nod to purposeful equipment selection can optimize performance, energy efficiency, and service speed. A simple, tangible step is to review the equipment options with a clear eye toward reliability and maintenance ease. As part of this process, consider visiting a guide that outlines how to choose food-truck equipment wisely. This resource can help you align your kitchen layout with expected workflows and service patterns, ensuring that you get the most out of every dollar spent. equipment selection for food trucks

As you translate these costs into a business plan, you will also want a targeted view of your local market. If you share a target city or region, you can break down the ranges for vehicle costs, permit fees, and labor rates to produce a more precise forecast. A side-by-side market comparison that weighs mobile catering against traditional catering in a given area can illuminate where your value proposition will land with clients. A straightforward profitability model can help you see how many events per month you need at a given price per person to cover fixed and variable costs, reach a desired margin, and achieve sustainable growth.

For readers seeking a deeper dive into the regulatory and financial framework, the SBA’s guide to starting a food truck business offers updated resources for permits, licensing, and financial planning. It is a practical companion to the narrative above and can be a reliable anchor as you finalize your business plan. You can access that external resource here: https://www.sba.gov/business-guide/plan-your-business/start-food-truck-business

In sum, the journey from a concept to a thriving taco truck catering operation hinges on balancing upfront investment with ongoing costs, while navigating a regulatory landscape that rewards preparedness. The lowest upfront price does not guarantee a favorable long-term outcome if maintenance, permits, and compliance are neglected. Likewise, a larger initial outlay can pay dividends in reliability, consistency, and customer trust when it translates into a well-designed kitchen on wheels, a compliant operating footprint, and a team aligned around a clear service promise. With thoughtful planning, disciplined cost control, and steady attention to regulatory demands, a taco truck business can blend the flexibility of mobile service with the reliability of established catering channels, delivering a compelling value proposition to weddings, corporate events, and community celebrations alike.

Chasing the Taco Price: How Location and Market Forces Shape Taco Truck Catering Costs

Prices for taco truck catering don’t exist in a vacuum. They emerge from a matrix of location, demand, competition, and the level of service a client expects. The same cart can bend under different skies depending on where it operates. In big cities with dense populations, high foot traffic, and stringent regulatory environments, the cost of doing business climbs. The same operation in a smaller town or rural setting faces lower overhead, looser permitting, and less intense competition, which often translates into more flexible pricing. Reading these geography-driven tides is essential for anyone planning to enter the field, price a menu, or decide what kind of vehicle to purchase. The numbers you see in a price sheet are not simply about the equipment; they reflect the environment in which the equipment runs, the permits that must be secured, the parking realities, and the expectations of a more discerning consumer base.

In major metropolitan areas—think cities with dense corporate campuses, frequent corporate events, and a vibrant festival calendar—the baseline costs of operation are elevated. Overhead rises with every permit, every insurance requirement, every license renewal, and every premium parking option that guarantees visibility and accessibility in crowded districts. These costs don’t disappear when a shift ends; they accumulate as fixed monthly and annual obligations. A truck that would be neighborly and affordable in a smaller market can become a more expensive proposition in a city where curbside exclusivity is often a paid privilege and where high-end catering standards push up prices through the need for superior ingredients, polished presentation, and extended service hours. The result is a pricing atmosphere in which event planners and corporate clients expect reliability, a quick turnaround, and a spotless, on-time service with meticulous branding and front-of-house presentation. In such markets, the tiered pricing you encounter—whether you are buying a kitchen-on-wheels unit or hiring a mobile caterer—tends to reflect not only the cost of the food but the value of seamless logistics and compliance.

The converse is equally instructive. In smaller cities or rural areas, operational expenses are spread over a less saturated demand curve. Permitting regimes may be simpler, with fewer fees or faster processing times. Parking can be easier to secure, with less competition for prime spots, and insurance costs can be lower due to fewer required coverages or simplified coverage packages. The result is a more forgiving pricing landscape. In these settings, operators may be able to offer more competitive per-person rates, shorter lead times, or more flexible menu options without compromising margins. The same street-side taco concept, when transplanted to a less crowded zip code, often finds a path to profitability through volume-based pricing, easier logistics, and the opportunity to build long-term relationships with local organizations—schools, community centers, and neighborhood events—that value consistency and cost predictability over premium branding alone.

Against this geographic backdrop, market variability becomes the second major driver of price. Corporate events and weddings in well-off neighborhoods typically push catering budgets higher. Clients who expect a white-glove service, a chef-curated menu, and premium ingredients are often willing to invest more per guest when the experience promises customization and impeccable presentation. In these scenarios, per-person pricing commonly lands in a premium range, often cited in the industry as a broad bracket from the mid-teens to the mid-twenties per guest, depending on the level of service and the menu’s sophistication. In practice, this means a catered taco experience can transform from a casual, quick-service moment into a tailored culinary event, complete with branding, specialized service staff, and perhaps even live cooking stations. The logistics become more complex, but so do the revenue opportunities if the client’s expectations align with the operator’s strengths.

On the other end of the spectrum lie casual gatherings, school fundraisers, and local festivals, where price discipline and efficiency matter most. For these occasions, pricing is often driven by volume and speed rather than the premium experience. Operators may offer simpler menus, streamlined service, and bulk pricing designed to move large crowds quickly. In these contexts, per-person rates typically fall into the eight-to-twelve-dollar range, reflecting simpler service models, the use of standard ingredients, and scalable production that can reliably meet a surge of demand. The economics here hinge on throughput—the ability to serve many people efficiently while managing waste, labor, and ingredient costs. Even when the crowd size is large, the focus is on delivering value through dependable consistency rather than bespoke customization.

To navigate these tides, many operators adopt a layered pricing approach that accommodates both the variability in demand and the client’s willingness to invest. This often translates into multiple pricing structures—per-event flat fees for guaranteed inventory and staffing, tiered per-person pricing for different menu packages, and add-ons for premium components such as avocado-forward toppings, specialty salsas, or custom branding with a client’s logo and color scheme. A sensible strategy recognizes the distinct value a taco truck brings: mobility, speed, and a theater-like experience where live cooking and aroma entice a crowd. When customers value these attributes, they are often willing to pay for speed and spectacle as much as for flavor. But when budgets tighten or the audience is more price-sensitive, operators can lean on menu simplification, self-serve beverage stations, or extended service windows to reduce costs without sacrificing core quality.

This nuanced pricing reality also highlights the importance of knowing the base equipment landscape before weighing a catering price strategy. The initial research landscape outlines several baseline equipment price bands that most buyers encounter when considering a taco catering trailer or cart: basic taco food carts starting at around 1,680 dollars for bulk purchases, standard fast-food trailers ranging roughly from 5,200 to 8,000 dollars for a single unit, and more comprehensive full-kitchen mobile trailers starting near 2,950 dollars per piece. These figures provide a practical foundation for estimating upfront investment and depreciation, but they are only one half of the story. Ongoing costs—insurance premiums tied to corporate event work, maintenance, fuel, driver wages, and the cost of high-quality ingredients—shape the real-world profitability of any catering operation. A robust price model must factor these recurring expenses and adjust margins accordingly as market conditions shift.

To place pricing in a broader industry context, current market research is essential. The National Restaurant Association’s 2024 Mobile Food Vendor Market Report offers a granular view of regional pricing, service models, and demand patterns across the country. While this chapter cannot reproduce every nuance of that report, it underscores a central truth: pricing is a living parameter, responsive to region, season, event type, and consumer sentiment. For a detailed study, this external resource is a valuable compass for operators seeking to calibrate their expectations and refine their pricing forecasts in real time: https://www.restaurant.org/research/market-reports/mobile-food-vendor-market-report-2024. Reading such a report alongside local market data helps operators avoid overpricing in sluggish markets and underpricing when demand spikes.

From a practical standpoint, the pricing conversation also benefits from a forward-looking mindset focused on profitability. For operators who want to translate pricing insights into sustainable growth, a few guiding principles matter. First, align price with value. If a client seeks a premium, chef-driven experience with customized menu design, branding, and high-end ingredients, the cost should reflect the added value. Second, manage variable costs with disciplined sourcing and forecasting. Ingredient costs swing with seasonality and supply chain pressures; building a menu with adaptable staples and flexible substitutions helps maintain margins. Third, optimize the service model. Efficient staffing and streamlined kitchen layouts reduce labor costs and improve service speed. Fourth, communicate clearly. Transparent pricing with defined inclusions—what’s included in the per-person price and what constitutes an add-on—prevents disputes and reinforces trust with clients.

For operators navigating these decisions, I offer a practical navigational aid. Consider a tiered pricing framework that mirrors market expectations while preserving margins. A base per-person rate for a simple, fast-service menu in a mid-range market can be complemented by add-ons such as premium toppings, branded décor, and special dietary accommodations. In high-demand urban markets, create a separate premium tier that reflects intensified overhead and elevated client expectations. In rural or smaller-market environments, emphasize value through reliable service, speed, and predictable portioning, using volume-based discounts where possible. This approach allows a single operation to flex with market conditions rather than being locked into a single price point.

For readers looking to deepen their strategy, the internal resource on profitability trends offers a complementary perspective. It highlights how savvy owner-operators track costs, test pricing models, and adapt to shifting demand across regions. See the discussion here: unlocking profitability essential trends every owner-operator needs to know in 2025.

In sum, pricing for taco truck catering is a dynamic equation driven by geography and market demand. The same mobile kitchen that thrives on a sunlit street corner can command a different price when parked outside a corporate campus at rush hour. The most successful operators treat price as a flexible instrument—one that signals value, covers overhead, and aligns with client expectations. They build pricing models that anticipate regional variance, leverage the pull of premium events without scaring away price-sensitive audiences, and maintain a lean operating backbone to protect margins. The regional map may bend, but sound pricing principles—clarity, value, and adaptability—remain constant.

External resource for further reading: https://www.restaurant.org/research/market-reports/mobile-food-vendor-market-report-2024.

Final thoughts

Understanding how much for taco truck catering requires more than a single quote. By anchoring expected costs with price ranges, recognizing how equipment choices affect spend, evaluating new versus used options and financing, accounting for ongoing permits and compliance, and factoring geographic market differences, you gain a realistic budget and a clear path to profitability. The takeaway is simple: approach pricing as a layered decision set. Start with the baseline you can afford, then layer in equipment, permits, and location dynamics to build a sustainable mobile-kitchen business. With thoughtful planning, your taco trailer can move from dream to dependable income in a way that serves urban commuters, outdoor enthusiasts, freelancers, and first-time buyers alike.