The trucking industry is currently facing significant challenges, particularly in how tariff surcharges are affecting equipment costs. A striking example is Volvo’s recent announcement of a $3,500 tariff surcharge on new VNL trucks. This additional cost, while substantial, barely scratches the surface of the financial burden that manufacturers endure due to tariffs.

As companies navigate this evolving economic landscape, the implications of such surcharges are far-reaching; they not only impact manufacturers but also cascade down to equipment buyers and fleet operators. With the supply of tariff-free inventory dwindling, the $3,500 surcharge exemplifies a critical juncture for the trucking industry, pushing buyers to reconsider their investments and operations amidst rising costs and economic uncertainty.

Understanding the effects of the Volvo tariff surcharge is essential for anyone involved in the trucking sector, as it marks a pivotal moment in their purchasing strategies and profitability trajectories.

Peter Voorhoeve, president of Volvo Trucks North America, commented on the challenges of covering tariff costs, stating, “That doesn’t really cover all the cost [of the tariffs], but that’s all we can do for the moment. It puts pressure on margins as well, by the way, which you will see in the industry at large.” This highlights the pressure that tariff surcharges exert not only on manufacturers like Volvo but also on the entire trucking industry as they navigate rising costs and pricing strategies.

The long-term outlook for truck pricing is fraught with uncertainty amid rising tariffs and evolving market conditions. As Peter Voorhoeve, president of Volvo Trucks North America, stated, “I believe the tariffs will continue to increase the cost of the trucks. My message would be, I don’t think that the cost of new trucks will ever be lower than where it is right now.” This quote encapsulates the critical concerns surrounding the future of truck pricing and highlights the necessity for businesses to adapt their strategies in light of these challenges.

Recent trends in truck and trailer sales are showing significant effects from tariff surcharges. The data highlights problems such as declining net orders and delivery issues due to heightened costs from tariffs.

Summarized Findings Regarding Truck and Trailer Sales

Trailer Sales Data

- In May 2025, U.S. trailer net orders dropped 34% month-over-month, reflecting deeper seasonal effects than typical, yet still remained 3% up from the prior year amid a weak May 2024 performance. Order cancellations reached a high of 37.6%, indicating retailers’ struggles with high costs.

- By July 2025, the decline continued with a 39% drop in net trailer orders compared to June, even as year-to-date orders showed an increase of 31% year-over-year.

Truck Sales Data

- In the first quarter of 2025, Traton experienced a 10% drop in truck deliveries, attributed to market uncertainties surrounding tariffs.

- In the third quarter of 2025, Daimler Truck observed a nearly 40% reduction in North American sales, corresponding to ongoing economic pressures.

Impact of Tariffs on the Market

- In August 2025, tariffs on steel and aluminum were raised to 50%, causing rising manufacturing costs and resulting in extended fleet replacement cycles, exacerbating already weak demand.

- A planned 25% tariff on medium and heavy-duty trucks announced for November 2025 is expected to cause further market strain.

- Carriers reduced fleets by an average of 2.2% in 2024 and continued this trend into 2025, which is a direct response to the dwindling demand as affected by tariff burdens.

- Additionally, the consensus among dealers is one of caution; the uncertainty related to tariffs makes them hesitant to invest in stock that may depreciate in value.

Overall, these findings clearly show that tariff surcharges are influencing market dynamics profoundly by increasing equipment costs, causing order reductions, and leading to strategic shifts within the truck and trailer industry.

Strategies for Managing Tariff Impacts on Trucking Purchases

Managing tariff surcharges in truck purchases and fleet operations requires a multifaceted approach. Below are strategies and insights to navigate these challenges effectively:

1. Strategies for Managing Tariff Surcharges in Truck Purchases:

- Utilize Foreign-Trade Zones (FTZs): FTZs allow businesses to defer, reduce, or eliminate tariff payments by treating goods stored or processed within these zones as outside U.S. Customs territory. This can improve cash flow and lower overall import costs. Learn more.

- Implement Tariff Engineering: Modifying product designs or material sourcing can reclassify goods under lower-duty tariff codes, potentially reducing tariff liabilities. There are several methods to achieve this:

- Material Substitution: Replacing tariffed materials with alternatives can lead to lower duties. For instance, substituting certain grades of steel with advanced polymers may reduce tariff exposure.Read about this strategy.

- Product Classification Optimization: Minor design changes can help reclassify products under lower tariff codes. For instance, enhancing certain aspects of a truck engine might qualify it for a different classification.Explore more on effective changes.

- Diversify Supply Chains: Sourcing components from multiple regions can minimize exposure to tariffs imposed on specific countries.Get insights here.

2. Bulk Purchasing Advantages:

- Cost Savings: Consolidating multiple purchases into a single lease or loan package can simplify payment schedules, offer leverage in negotiating vendor discounts, and reduce overall financing risk by spreading it across assets. Find out more.

- Negotiation Leverage: Committing to high shipment volumes can provide leverage to negotiate better terms with carriers, resulting in reduced overall expenses. Learn how to negotiate effectively.

3. Financing Options for Fleets:

- Lease-to-Own (LTO) Programs: These structures allow businesses to lease equipment for a defined period with a pre-arranged purchase option at the end of the term, spreading out costs while providing ownership certainty. Benefits include lower monthly lease payments and the option to upgrade or walk away. More details here.

4. Examples of Successful Fleet Management Amid Tariff Surcharges:

- Proactive Vehicle Replacement: Avoiding delays in vehicle replacements can prevent higher costs and operational disruptions. For instance, during the COVID-19 pandemic, fleets that extended asset lifespans faced more frequent breakdowns and longer downtimes. Discover effective replacements.

By integrating these strategies, businesses can effectively manage tariff surcharges, optimize fleet operations, and maintain financial stability in a fluctuating trade environment.

| Manufacturer | Surcharge Amount | Notes on Policy |

|---|---|---|

| Volvo | $3,500 | Covers only part of tariff costs; additional pressures noted. |

| Peterbilt | $4,000 | Competitive pricing strategy; subject to change based on tariffs. |

| Kenworth | $3,800 | Offers financing options to offset surcharges. |

| Freightliner | $3,500 | Same as Volvo; aligned with tariff impact factors. |

| Mack | $3,700 | Emphasizes fuel efficiency and value addition to justify surcharge. |

| International | $3,600 | Incentivizes bulk purchases to mitigate additional charges. |

| Hino | $3,200 | Lower surcharge; focuses on market share during tariff fluctuations. |

Image showing modern truck sales technology that reflects innovation in the trucking industry, evoking the theme of progress amidst hurdles.

Long-Term Impacts of Tariffs on the Trucking Industry

Tariffs significantly affect the trucking industry. They influence pricing, supply chain dynamics, and future investment strategies. As financial barriers persist, businesses navigate a transformed economic landscape filled with both challenges and opportunities.

Pricing Dynamics

One immediate effect of tariffs is the rise in prices for trucks and trailers. Tariff increases on imported steel and aluminum can add tens of thousands of dollars to the cost of new equipment. For example, tariffs on imported vehicles can lead to an increase of up to $35,000 for a new truck. These costs place a heavy burden, particularly on small carriers and fleet operators. Higher shipping costs may eventually be passed on to consumers, leading to squeezed margins for the carriers. This situation makes operational efficiency critical.

Supply Chain Disruptions

Tariffs disrupt established supply chains. Trucking businesses often must seek alternative suppliers or rethink their sourcing strategies to reduce costs affected by tariffs. This can lead to logistical inefficiencies and delays due to adjusted supply chains. Customs processing times may increase, complicating service reliability in a competitive market. Companies reliant on international suppliers face disadvantages as they adjust their routes and partnerships to find cost-effective alternatives.

Future Investments

The uncertainty surrounding tariffs has made many companies cautious about investing. Major truck manufacturers are revising their 2025 forecasts downward, anticipating continued tariff complications. Truck orders have plummeted, with some categories reporting drops of over 50% year-over-year. Companies that think ahead might focus on optimizing their current fleets and approach expansions carefully until there is clarity about future tariff directions.

User Adoption and Market Responses

Recent data shows user adoption trends reflecting these tariff challenges. A noticeable number of trucking industry players are cutting back on new purchases due to heightened financial pressure. Major declines in truck sales and significant order cancellations indicate a market recalibrating amid uncertainty. Fleet operators may delay replacing aging equipment, potentially impacting long-term operational efficiency. The current economic climate may push companies toward leasing arrangements instead of outright purchases to mitigate financial burdens.

In summary, tariffs have profound long-term impacts on the trucking industry. They alter pricing structures, disrupt supply chain logistics, and influence future investment decisions. To thrive amid these economic challenges, stakeholders must stay adaptable and strategic, leveraging insights from market responses.

Conclusion

In review of the discussed strategies for managing tariff surcharges in the trucking industry, it is clear that businesses face numerous challenges in adapting to rising costs and changing market dynamics. The Volvo tariff surcharge is a significant case in point, as it exemplifies the broader implications of tariff policies on pricing and operational strategies.

Effective approaches for managing these surcharges include utilizing Foreign-Trade Zones, which can alleviate the financial burdens by deferring tariff payments, and employing tariff engineering to optimize product classifications and reduce costs. Additionally, diversifying supply chains is crucial to mitigate risks associated with tariffs imposed on specific countries.

On the financing side, strategies like lease-to-own programs and bulk purchasing can provide vital advantages, enabling companies to spread out costs and negotiate better terms, thus maintaining cash flow and investment potential. Moreover, proactive fleet management practices, such as optimizing route efficiencies through telematics, help in navigating the complexities presented by tariffs.

As the trucking industry continues to grapple with these surcharges, reflection on current strategies is vital for companies aiming to thrive in an era of uncertainty. The ongoing evolution of market conditions highlights the importance of adaptability. Businesses that internalize these strategies and actively monitor market trends will foster resilience, ensuring that they can successfully maneuver the financial implications of tariffs in the long run.

Image showing modern truck sales technology that reflects innovation in the trucking industry, evoking the theme of progress amidst hurdles.

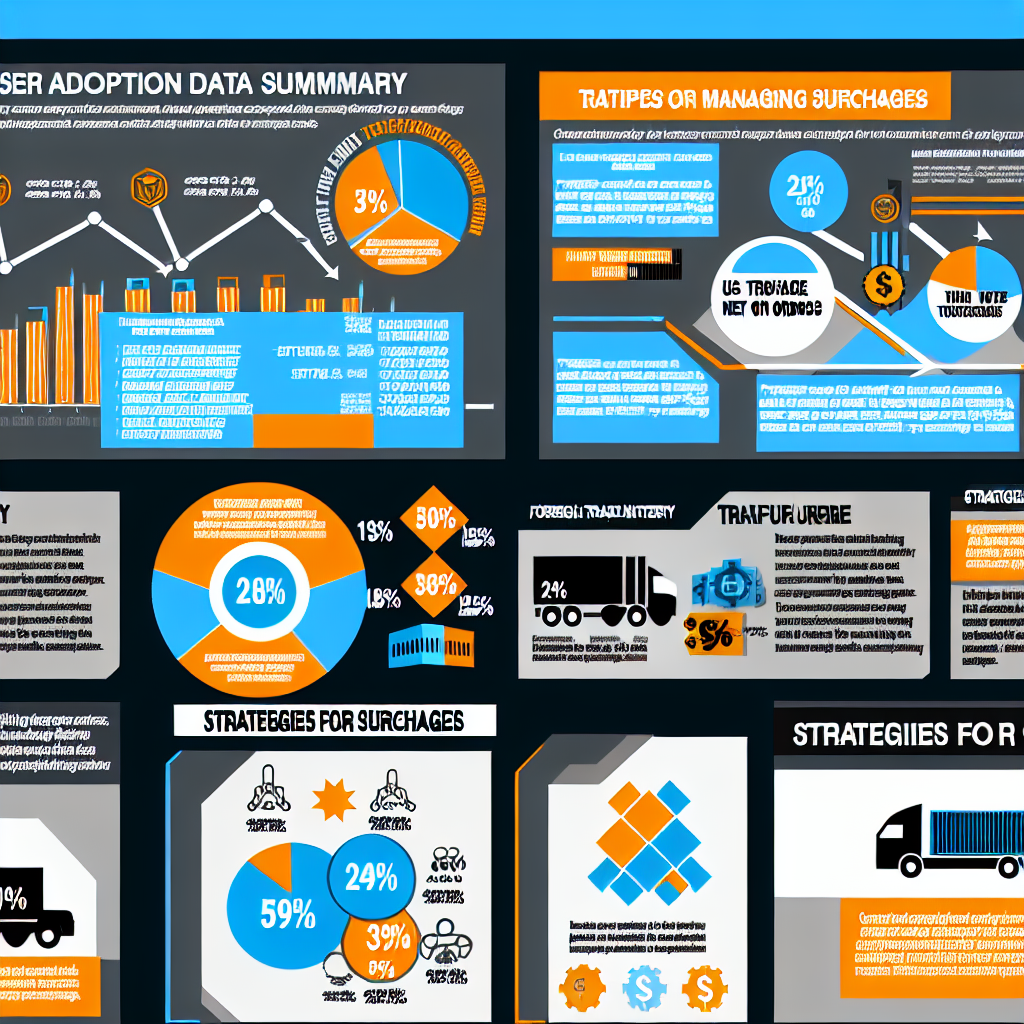

Infographic summarizing user adoption data and effective strategies for managing tariff surcharges in the trucking industry.

Infographic representing strategies for managing tariff surcharges in the trucking sector.

Conclusion

In review of the discussed strategies for managing tariff surcharges in the trucking industry, it is clear that businesses face numerous challenges in adapting to rising costs and changing market dynamics. The Volvo tariff surcharge is a significant case in point, as it exemplifies the broader implications of tariff policies on pricing and operational strategies.

Effective approaches for managing these surcharges include utilizing Foreign-Trade Zones, which can alleviate the financial burdens by deferring tariff payments, and employing tariff engineering to optimize product classifications and reduce costs. Additionally, diversifying supply chains is crucial to mitigate risks associated with tariffs imposed on specific countries.

On the financing side, strategies like lease-to-own programs and bulk purchasing can provide vital advantages, enabling companies to spread out costs and negotiate better terms, thus maintaining cash flow and investment potential. Moreover, proactive fleet management practices, such as optimizing route efficiencies through telematics, help in navigating the complexities presented by tariffs.

As the trucking industry continues to grapple with these surcharges, reflection on current strategies is vital for companies aiming to thrive in an era of uncertainty. The ongoing evolution of market conditions highlights the importance of adaptability. Businesses that internalize these strategies and actively monitor market trends will foster resilience, ensuring that they can successfully maneuver the financial implications of tariffs in the long run.

Call to Action: Stay informed about tariff adjustments and continually assess how your operations can adapt to provide greater efficiency and cost-effectiveness. Embrace these strategies today to ensure your fleet remains competitive and profitable in the challenging economic landscape.

Volvo Trucks North America has implemented a tariff surcharge of $3,500 on new vehicles, primarily to mitigate the increased costs associated with tariffs on imported components. This surcharge does not fully cover the financial burdens incurred by the company, indicating broader challenges in the industry.

Since the launch of the redesigned Volvo VNL in January 2024, the company has successfully produced approximately 16,000 units. This model signifies a significant transformation, as it boasts a 90% new component design meant to pave the way for future powertrain advancements in the North American market.

Volvo has invested $400 million to develop a cutting-edge cab plant in Dublin, Virginia, reinforcing its commitment to leading innovation in heavy-duty trucking.

Moreover, the new VNL is expected to enhance fuel efficiency by up to 10%, with improvements stemming from aerodynamic designs and powertrain enhancements, promising substantial fuel cost savings for fleet operators.

This combination of tariff adjustments and production initiatives highlights Volvo’s strategic efforts to navigate the current economic landscape and position itself for future success.

Infographic summarizing user adoption data and effective strategies for managing tariff surcharges in the trucking industry.

Infographic representing strategies for managing tariff surcharges in the trucking sector.