Urban life demands meals that travel well, taste bold, and fit into a busy schedule. Taco truck burritos deliver on all three: they’re hearty, highly customizable, and built for speed. This guide breaks the craft into five chapters that align with the realities of city living, outdoor trips, and micro-entrepreneurship. You’ll explore core fillings and proteins for authentic flavor, master assembly and tortilla warmth, scale up through batch cooking, balance textures with smart toppings and sauces, and finish with packaging that keeps heat and flavor intact on the go. Each chapter ties directly back to the central aim: empower you to recreate a taco-truck experience—bold, portable, and dependable—whether you’re commuting, running a side hustle, or simply feeding a crowd after a day outdoors. Start with flexible filling options, move through precise assembly, optimize for volume, refine toppings, and finish with packaging that mirrors street-food authenticity. Ready to roll into a world of flavorful, practical burritos that fit every urban lifestyle? Let’s dive in.

Chapter 1: From the Line to a Handheld Feast — Mastering Core Fillings and Authentic Proteins for Taco Truck Burritos

The line of a taco truck is a moving theatre of scent and rhythm. A customer orders with a glance and a word, and within moments a warm burrito appears, neatly wrapped and bursting with confident, unmistakable flavor. Reproducing that experience at home starts not with gimmicks, but with a deliberate choice of core fillings and proteins that mirror the balance and boldness of street-grade burritos. The aim is a handheld meal that remains cohesive as you bite through the tortilla, its components harmonizing rather than competing for attention. In this chapter, we lean into the foundational proteins and fillings that undergird a real taco truck burrito. We’ll navigate not just what to fold inside, but how those elements interact: how a citrus-bright carne asada, a slow-braised carnitas, or a spiced al pastor can anchor a whole, well-structured burrito when wrapped in a pliable tortilla and warmed just so. The result should feel both familiar and elevated, a bridge between fast-service efficiency and the artisanal focus that makes a truck burrito memorable.\n\nBegin with protein, the backbone of the burrito. Carne asada makes a dramatic first impression. A lean flank or skirt steak, when marinated in a bright blend of citrus, garlic, and a handful of ground spices, arrives at the griddle with a tang that cuts through richness and invites toppings to follow. The sear should give a light char, a whisper of smoke that carries across the fold of tortilla. When you slice the steak, the interior remains juicy, offering a chew that anchors the bite without becoming dense or dry. The key is to rest the meat briefly after cooking; that pause lets the juices redistribute, so every mouthful lands with even flavor rather than a rush of heat or salt only at the edges. Carve the meat into thin strips or small dice so it layers smoothly with the other components, and consider keeping it slightly under-warmed rather than piping hot. A burrito is a shelter for moisture and texture, not a blowtorch of heat.\n\nCarnitas presents a different kind of magic. Slow braising pork shoulder in rendered fat creates a richness that feels almost velvet on the palate. The technique yields meat that is deeply savory, with a shy sweetness and a pleasing amount of fat that helps keep the burrito moist as you eat. The finishing crackle—an intentional crisping of the exterior—adds a textural contrast that makes the filling feel substantial. For home cooks, the trick is in the braise: a steady, low simmer with aromatics—garlic, onion, bay, and a splash of citrus—creates a pork that shreds easily yet retains a pleasant bite. Shred and fold the meat with a light touch to avoid a mush of texture, and let the residual fat lightly glaze the other fillings, so the burrito doesn’t feel dry before it reaches the last bite.\n\nAl pastor offers a brighter, tangier alternate path. A blend of dried chiles, pineapple juice, achiote, and cinnamon gives al pastor a distinctive aroma and a balance of spicy, sweet, and acidic notes. Traditionally cooked on a vertical spit, home cooks can approximate the effect by a quick, high-heat sear to caramelize the exterior after a marinading period. The pineapple’s sweetness should be restrained, not dominant—enough to lift the meat, not so much that it competes with the salt and chili. If you’re cooking al pastor at home, consider a light glaze toward the end to collect a little caramel along the edges; this creates a glossy, appetizing surface that translates well when wrapped. The bright tang of al pastor makes a burrito feel lively, almost celebratory, and it pairs brilliantly with a simple bean-and-rice base.\n\nChorizo, where you want a deep, smoky backbone with a kick, can lift the entire assembly. Mexican chorizo—crumbled, seasoned sausage rather than a cured version—delivers a robust, peppery heat that doesn’t overpower the other components. It browns quickly and renders fat that bastes the surrounding fillings as the burrito heats. Use it sparingly if you’re including other spicy elements; you want the flavor to be a chorus, not a solo. If you’re aiming for a leaner experience, you can blend chorizo with lean ground meat, which softens intensity while maintaining a recognizable chili-driven character.\n\nPollo asado, or grilled chicken, stands as a lighter option that still delivers a satisfying, citrus-laced snap. A simple adobo-style marinade—chiles, vinegar, garlic, and oregano—adds brightness and moisture. Chicken’s milder profile makes it an ideal partner for fresh toppings like cilantro, onion, and avocado, while still holding its own amid beans, rice, and cheese. Grill the chicken to a gentle char rather than a hard crust; you want a surface that contributes aroma and texture without locking in dryness. Slices or small chunks work well in the burrito, keeping the bite coherent with the rest of the filling.\n\nBeyond protein, core fillings do the steadying work that makes a burrito feel substantial and balanced. Pinto or black beans give fibrous texture and earthiness, and when properly seasoned they form a binding agent between meat and starch. The beans should be simmered with a touch of garlic, cumin, and a bay leaf or two, then mashed lightly in places to help the burrito hold together. They cushion the mouth with creaminess and ensure that each mouthful carries a hint of roasted legume scent that is unmistakably Mexican in character. Rice, too, plays a crucial role. A lightly seasoned white rice with onions and a whisper of cumin acts as a stabilizing layer, soaking up fat and providing a gentle counterpoint to chili-driven fillings. It should be fluffy, with grains intact, so you can distribute it evenly within the tortilla without creating a dense mass at the center.\n\nA traditional, sometimes defining element is a chili con carne or a beef-and-chili filling that unifies the burrito’s interior with a consistent, savory backbone. If you choose to add it, keep the ratio modest and let the chili’s acidity come through in balance. The idea is not to drown the other components but to give the burrito a sense of place—the Tex-Mex lineage that many people associate with the street-food burrito. Together, these fillings must interact with the tortilla in a way that encourages a clean wrap, not a burst of loose ingredients. The tortilla should cradle the content and still fold with ease when you roll.\n\nToppings are the final brushstrokes on a taco truck burrito canvas. Fresh cilantro, diced onion, and chopped tomatoes add brightness. A dollop of avocado or a smear of guacamole provides creaminess that complements the heat. A modest sprinkle of shredded cheese—think Monterey Jack or a mild cheddar—adds richness without overwhelming the filling. Salsas, whether bright verde or deeper red varieties, function as a finishing note rather than a structural element. They should be applied sparingly on the toppings to avoid soaking through the tortilla and making the outer layer soggy. A squeeze of lime just before serving brightens the whole assembly and ties the flavors together, echoing the citrusy notes found in many authentic fillings.\n\nThe method of assembly matters almost as much as the ingredients themselves. Start with a warmed tortilla, pliable and ready. Place a generous bed of rice in the center, followed by beans, then a layer of the chosen protein. A light scatter of cheese on top helps bind the layers as it melts. Add the toppings in a way that keeps moisture near the surface rather than leaking into the center. Roll the burrito tightly, turning in the sides as you progress to ensure a compact, transportable shape. If you’re serving it hot, a quick seal on the seam side in a dry skillet can help maintain structure and create a subtle crust—without dried edges or burnt spots. If you’re meal-prepping, wrap the burrito in foil or parchment to hold the form and keep the heat contained; this also makes for easy reheat in a skillet or oven, preserving the interior integrity while restoring a gentle warmth to the outside.\n\nThe beauty of this approach is its scalability and adaptability. Batch-cooking the components allows you to accommodate varying appetites and dietary needs, from lean proteins to more indulgent combos, and from plant-based substitutions to full meat-forward burritos. The same structure—core fillings with a protein on top, a buffering layer of beans and rice, and fresh toppings—remains the backbone of a burrito that would sit comfortably on a bustling line or a quiet kitchen counter. And while the overall flavor should feel bold and street-inspired, the home kitchen offers the opportunity to dial in sweetness, acidity, heat, and creaminess to suit personal taste without losing the essence of a taco truck burrito.\n\nFor further context about how professional mobile food operations optimize sustainability and efficiency without sacrificing flavor, consider exploring sustainable practices for mobile food trucks, a resource that discusses practical approaches to operations that align with the same flavor-forward philosophy described here. The connection between technique, efficiency, and taste is not incidental; it echoes the expectations customers bring to a burrito eaten on the go and inspires a disciplined approach to planning, prep, and presentation. This is where the home cook can translate a truck’s energy into a reliable, reproducible, and deeply satisfying meal.\n\nTo widen the dialogue beyond the kitchen, you can consult broader home-to-truck parallels in the field of mobile food services, which offer insights into timing, equipment, and workflow. For readers seeking broader inspiration on authentic techniques and ingredient choices for carne asada, carnitas, and related components, a trusted guide to tacos and burritos at home provides a complementary perspective on building flavor foundations with confidence. External resources can illuminate nuances such as marination times, exact spice blends, and fry-and-fat management that enrich the core content presented above, helping you refine your own taco truck burrito program in a home setting.

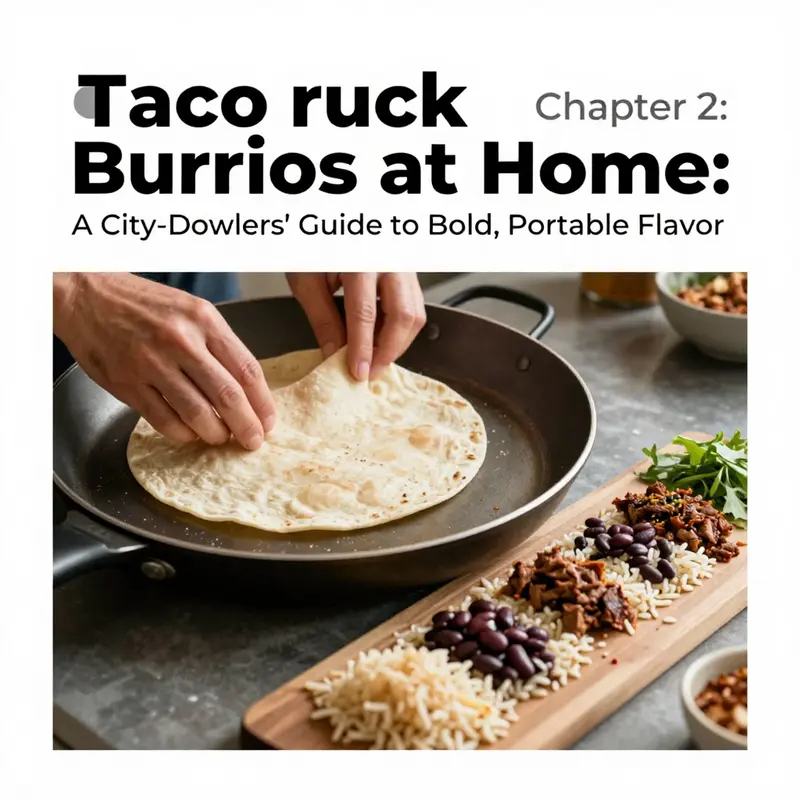

Chapter 2 — Rolling with Precision: Assembly Mastery and Tortilla Warmth for Taco Truck Burritos

When you chase the taco truck burrito experience, the magic doesn’t just sit in the meat or the sauce. It lives in two quiet acts that happen in sequence: the warmth of the tortilla and the discipline of assembly. The first act creates a pliable canvas; the second sets up a reliable rhythm that guides every burrito from station to stomach with the same bite and balance. In a busy kitchen or a home setup aiming for that street-food precision, embracing a deliberate, almost choreographed approach to assembly can transform simple ingredients into a coherent, portable meal that travels well and tastes loud and fresh with every bite.

Tortilla warmth is the hinge. The tortilla serves as the wrapper, the vehicle of everything inside, and, crucially, the binding force that keeps the filling together through handling and transport. A tortilla that is too cold or too dry tears easily; one that is overheated tethers moisture into a soggy center. The goal is pliability—tortillas that yield to folding without collapsing, yet resist cracking when stressed in a busy service line. For taco truck burritos, flour tortillas in the 10–12 inch range are typically preferred for their generous wrap-ability and sturdy bite. Keep them in a controlled warmth, not a hot hold, so they remain romantic and flexible rather than rubbery or brittle. A light, even warmth helps activate surface oils and makes the tortilla receptive to the binding that comes with a modest sauce or oil if you choose to use one.

The warming method you choose matters as much as the filling you choose. In high-volume settings, the most dependable path is a two-stage approach: pre-warm or hold pliable tortillas in a steady, low-heat environment, then perform quick, individual warms on the line as each burrito comes together. Dry skillets or comals produce a classic, authentic aroma and surface gloss, but they demand attentiveness; a steady griddle line with a gentle stack of tortillas wrapped in a clean towel can keep pliability intact for several minutes. If you’re batching, steamer boxes or tortilla warmers offer uniform moisture and consistent pliability across dozens of tortillas, with far less hand heat required per unit. Whichever method you adopt, the objective remains the same: uniform pliability that supports a clean, confident roll. A short, purposeful warm on each tortilla—15 to 45 seconds per side depending on thickness—will be enough to unlock its flexibility without cooking out all softness.

Mise en place forms the backbone of smooth assembly. Before any filling touches the tortilla, you should know exactly how much of each component you’ll build into every burrito. Pre-portion proteins, beans, rice, and toppings into clearly labeled, shallow wells or small bowls. This isn’t just about speed; it’s about consistency. The hot components should stay hot enough to deliver a fresh bite, while the vegetables and salsas should present crisp texture and bright color. A light binding layer—such as a thin smear of sauce or a tiny brush of oil across the center—can help bind fillings and prevent soggy pockets, but use it sparingly. Too much moisture in the wrong place will wick into the tortilla and soften it unevenly, complicating the roll and dulling the experience bite after bite.

The assembly line itself benefits from a simple, repeatable rhythm. Imagine the burrito as a compact package that must travel a short distance from wrap to finish without losing its shape. In a home or small commercial kitchen, dedicate a single station to warming, a second to filling, a third to rolling, and a final one to wrapping and holding. Even this pared-down layout yields tangible gains in consistency. When you assemble, begin by checking the tortilla’s pliability; if it’s not naturally supple, a quick edge warm or a light re-warm on the entire surface can restore it. Then lay the tortilla flat and position your core fillings in a deliberate, evenly distributed column down the center. A typical, well-balanced build might place about 1/3 cup of cooked rice, 1/3 cup of pinto beans, and 4–6 ounces of seasoned protein in a mid-size burrito, followed by a modest sprinkle of cheese, and then toppings that add brightness and texture. Don’t overload the center; you want bite and cohesion, not a leak-prone mosaic.

Moisture management is the silent partner to warmth and filling balance. Sauce placement matters. A thinner sauce can knead into the rice and beans, while a thicker finishing sauce can crown the burrito without saturating the core. Distribute wetter toppings toward the outer ring and reserve drier or more absorbent components toward the middle to wick away moisture where needed. Dice vegetables to uniform size so they heat evenly and contribute consistent texture. When you layer, think of the burrito’s cross-section: the center should deliver the protein and grains with a gentle binding in place, while the edges offer freshness and crunch that won’t flood the wrap.

Now to the heart of the matter—the roll. The two-handed method is practical and reliable. Start by folding the bottom edge of the tortilla up toward the center, creating a seal that traps the filling. Then fold the sides inward, keeping the fillings tight and centered as you work. Begin rolling away from you with steady, even pressure, tightening as you go so that the burrito forms a compact cylinder. As you reach the seam, press the edge of the tortilla to seal. If you’re serving hot or on the move, a light wrap of foil near the seam can help stabilize the roll for transport and handling. The finishing touch is a calm, deliberate hold: set the burrito seam-side down so the seal has a moment to set and the contents settle. In certain operations, a brief post-roll heating on a gentle surface—just long enough to re-knit the seam—can improve overall cohesion without overcooking the interior.

A properly wrapped burrito should feel sturdy in your hands and yield cleanly when bitten. This requires thinking ahead about moisture and structure during assembly. If a burrito risks leaking, revisit the order of fillings and consider a second reduction in sauce or the addition of a small, dry layer of rice or beans near the center to absorb moisture. If the tortilla tears during wrapping, it’s a sign the wrap didn’t have enough pliability at the moment of roll; re-warming the tortilla briefly and reattempting the fold often resolves the issue. Conversely, if the burrito feels under-filled, recheck portioning and distribution; every bite should achieve a balanced profile rather than a pile of unevenly distributed ingredients.

Holding and presentation complete the workflow. Once wrapped, place burritos seam-side down to set the seal, then move them to a warm, breathable holding area that preserves moisture without letting the exterior become slick or glossy from condensation. Labeling becomes practical here, especially if you run multiple fillings. A simple system—color-coded wraps or clearly marked labels—helps staff quickly select the correct build in a busy service. If you want to optimize turnover and keep a steady pace, a few burritos can be pre-wrapped and placed in a shallow, ventilated tray to be finished with a quick sear or a gentle re-warm on the line. The goal is a uniform product that travels well and maintains integrity from tray to customer.

As you refine the process, you’ll notice two impulses that tend to separate proficient cooks from production teams: consistent portioning and a repeatable roll technique. The former minimizes deviation across dozens or hundreds of burritos; the latter preserves the burrito’s geometry, ensuring every bite meets the same expectations. To support consistency, many operations codify these choices into standard operating procedures (SOPs) that describe exact portion sizes, warming times, and rolling steps. Visual aids—photos or short videos—can anchor these SOPs in the minds of every team member and serve as quick references during a service rush. In practice, a brief practice session that mirrors peak pace can reveal bottlenecks and opportunities to streamline. The aim is not to rush but to create a rhythm that feels effortless and reliable, even when orders pile up.

In this context, equipment decisions—such as choosing the right warming bins, steam or dry-heat methods, and wrapping materials—play a larger role than many expect. A well-chosen warming setup minimizes handling, reduces moisture variance, and sustains pliability across a long service window. For those seeking guidance on equipment choices, consider resources that emphasize practical reliability and scalability in a food truck environment. Choose Food Truck Equipment Wisely can offer practical perspectives on selecting tools that align with your assembly rhythm and service goals. This chapter’s focus on technique is complemented by smart gear choices that ensure your burritos travel with the same integrity you build them with on the line.

To wrap up, the taco truck burrito experience hinges on a quiet, disciplined sequence that begins with warmth and ends with a tight, confident roll. The assembly is a choreography of balance and moisture, each burrito a compact statement of technique and taste. When you apply uniform portions, steady warmth, and a repeatable folding method, you can reproduce the same satisfying bite consistently—whether you’re cooking for a crowd of friends at home or running a small, seasonal window where speed and quality must coexist. For those who want to deepen their understanding of the broader craft and further refine their approach, there are many open resources and guides that explore practical, field-tested methods. A trusted reference in this space offers hands-on insights into authentic, truck-inspired burritos and can serve as a helpful companion as you scale your operation. External reference: https://www.tacocart.com/taco-truck-burrito-recipe

On the Line: Mastering Efficiency, Batch Cooking, and High-Volume Taco Truck Burritos

A taco truck burrito is more than a single recipe folded into a soft tortilla. It is a compact, mobile system designed to deliver a crave-worthy meal at speed, every time. In its essence, the burrito is a test of logistics as much as taste: how to stage a kitchen that fits on a truck, how to keep ingredients fresh during a long service, and how to assemble a dozen burritos that all taste like they came off a much larger, more meticulous operation. When you watch the best operators work, you see the same core principles at play—efficient workflow, smart batch cooking, and a service rhythm that respects both the queue and the palate. The burrito becomes a performance, and the kitchen a stage where volume and flavor perform in harmony rather than in competition. The challenge, and the opportunity, is to mirror the confidence of a busy street corner in a home setup, translating high-volume techniques into a kitchen that fits on a countertop or in a garage-sized space.

To begin with, the layout of a burrito workflow matters as much as the ingredients themselves. In a mobile setting, space is a premium, and every movement should count. The kitchen should feel like an assembly line designed for speed without sacrificing quality. Start with a clearly defined zone for each component: a cold prep area for tomatoes, onions, cilantro, and avocado; a grain and legume station for rice and beans; a protein station for the seasoned meat or its plant-based counterpart; a tortilla-warming station to keep the shell pliable without drying; an assembly station where the burritos take shape; and a finishing area for packaging and quick garnishes. When these zones are logically arranged in a smooth progression, the team spends less time chasing ingredients and more time building burritos. The geometry of the truck—narrow aisles, low clearance, and a fixed path between stations—becomes an ally rather than a trap, provided the equipment is chosen with attention to footprint and ease of cleaning.

Batch cooking is the backbone of any high-volume burrito program. Think in bulk, not in single servings. Rice and beans can be prepared in large quantities and held at proper temperatures, while proteins are browned, seasoned, and portioned in advance. The goal is to strip away repetitive tasks during busy minutes so the crew can focus on speed and accuracy when demand surges. For the rice, a simple bulk cook with steady soak and gentle simmer produces a fluffy base that can be portioned quickly into measuring cups. Beans benefit from a controlled simmer and a finishing touch of salt and aroma from a quick sauté of onion or garlic. Proteins—whether lean ground beef, turkey, or a plant-based alternative—should be browned in batches, then seasoned with a reliable taco mix and finished with a small amount of liquid to keep the mixture moist but not soup-like. Keeping these components warm and accessible within a warming tray or a stainless steel steam table supports continuous flow. When the components are prepped in large batches, the burrito assembly becomes a matter of timing rather than improvisation.

The tortilla is the wrapper that must perform under pressure. In the truck, tortillas need to be warm, pliable, and resistant to tearing as they encase a generous scoop of filling. The technique is simple but essential: lightly warm the tortilla just enough to bend, then keep it in a breathable wrap, or stack them with parchment so the next one remains ready. When a tortilla tears, it spoils the visual and mouthfeel of the burrito; when it remains pliable, the burrito holds its shape, cuts neatly, and travels well from window to customer. The amount of filling to place in the center should be consistent—roughly a measured portion that yields a balanced bite without overflowing. A burrito built with precision will roll tighter, slice cleaner, and stay warmer longer in transit. The stability of the wrap matters as much as the taste inside.

As the burrito comes together, the rhythm of assembly mirrors a well-rehearsed kitchen routine. One approach is to pre-measure the elements into small, labeled containers so each crew member can quickly grab what they need without pausing to weigh or measure. A typical target is to distribute roughly a third of a cup of rice, a third of a cup of beans, and a third of a cup of seasoned meat per burrito, then crown with a modest sprinkle of cheese, plus fresh toppings such as diced tomatoes, red onion, cilantro, and avocado. This approach achieves a consistent profile across dozens of burritos and reduces the chance of under- or over-stuffing. The toppings add brightness and contrast while remaining light enough to keep the burrito from becoming a heavy, clumsy package after a long shift. Fresh lime juice and a dash of hot sauce can brighten the finish without dominating the flavor, providing a restaurant-level lift that customers often expect. The finishing touch is always the call to wrap—rolling from the bottom to the top, keeping the sides tucked in as the burrito tightens with each pass. A quick wrap in foil or parchment then protects the burrito during transport, guiding it toward the customer with a neat, storm-ready exterior.

Designing for speed also means considering equipment and the physical ergonomics of the crew. Electric warming trays or low-profile steam tables can keep rice and beans at safe temperatures without scorching, while a well-tuned heat source for the meat ensures color and aroma stay vibrant from the first burrito to the last. The choice of equipment should align with the truck’s electrical load, power availability, and cleaning regime. In a bustling service, automation or semi-automation—such as a streamlined heat-and-wrap setup that helps lock in moisture and flavor while maintaining consistency—can be a worthy consideration. Even without high-end gear, the same principles apply: established, repeatable steps reduce hesitation, and thoughtful spacing reduces the amount of walking and bending required during peak periods. The operator who designs a workflow with measured steps, designated stations, and pre-portioned ingredients tends to see fewer bottlenecks and more satisfied customers.

The packaging phase closes the loop between kitchen and customer, and it is often the difference between a burrito that travels well and one that ends up soggy or messy. In a high-volume setting, trays with canopy lids or clamshell-style containers—designed to be microwaved and disposed of with minimal waste—are practical choices. The goal is to protect the burrito’s integrity while presenting it attractively enough to entice a quick purchase. Sustainability matters, so selecting packaging that can be recycled or composted where possible adds a layer of responsibility to the operation. The packaging also acts as a product showcase; a burrito placed neatly in a clear container invites a first bite that matches the first impression of aroma and color when the lid is lifted.

The beauty of this approach is its adaptability. It works as a blueprint for a busy truck, but it also translates to a home kitchen that dreams of scaling up. The method respects dietary needs by allowing easy substitution: low-fat proteins, plant-based options, or reduced-carbohydrate builds. Batch cooking handles a spectrum of preferences without requiring a complete menu overhaul. The same base system can support a rotating set of fillings, enabling a stall or home kitchen to maintain variety while preserving the efficiency that makes the burrito service so dependable. In practice, that means you can prepare a core set of components in bulk, then mix and match toppings to create distinct burrito profiles across the week. The key is discipline in staging, consistency in portions, and a constant eye on quality controls—tasting, texture, temperature, and moisture all aligned toward a reliable, repeatable product.

For operators building toward the real-world rhythm of a taco truck, the message is practical and precise: design the space to minimize movement, batch cook for predictability, and treat the assembly as a careful choreography rather than a random sequence of steps. The result is a burrito that carries the influence of high-volume kitchens—bold flavor, sturdy structure, and a satisfying weight in every bite—packed into a package that can travel from window to customer without losing its balance.

As you consider equipment, layout, and the timing of each component, keep the long-term goal in view: a system that yields consistent flavor and portion control while remaining adaptable to demand and dietary trends. The plan should be revisited after a busy shift, with feedback from staff and customers guiding tweaks to timing, temperatures, and assembly speed. The operators who embrace this iterative mindset—treating volume as a design constraint rather than a burden—are the ones who scale beyond a single truck to a dependable, repeatable standard for burritos on the go. When efficiency and flavor converge in this way, the burrito ceases to be merely a meal and becomes a reliable signal of a well-run, mobile kitchen that can sustain itself through busy nights and growing crowds. For anyone aiming to emulate the true taco truck burrito experience, the path is clear: optimize the workflow, master batch cooking, and honor the craft of fast, flavorful, and portable food.

To explore equipment decisions in context, operators can consider foundational guidance on choosing gear that aligns with mobile food service needs. A practical starting point is to examine resources that discuss equipment efficiency, electrical requirements, and layout optimization for mobile menus—especially those that address the realities of street-food operations with complex offerings. This approach helps ensure your burrito program remains scalable, consistent, and financially sound as demand grows. For further reading on mobile-truck design and technical specifications, see an external guide that dives into the technical specs and practical uses of complex menus in mobile setups. In the end, the burrito is a testable product, and its success rests on the clarity of the process behind it and the care with which it is executed on the ground.

Internal link for practical equipment guidance: Choose food truck equipment wisely.

External resource for deeper context on mobile-truck setups and technical specs: https://www.foodtruk.com/technical-specs-mobile-food-truck-complex-menus

Layered Craft: Toppings, Sauces, and Texture Harmony in the Taco Truck Burrito

The burrito that travels from a street window into a home kitchen is a study in disciplined layering. It isn’t enough to pile on tasty components; the real skill lies in balancing toppings, sauces, and texture so every bite delivers a chorus of warmth, crispness, creaminess, and brightness. When you walk through a taco truck line, you notice how the fillings look almost sculpted—there is a rhythm to the way rice, beans, meat, cheese, and fresh toppings come together that makes the burrito feel substantial without becoming soggy or unruly. Translating that rhythm into home preparation starts with a simple premise: keep moisture in check, build from the inside out, and respect the tortilla as the unifying medium rather than a mere wrapper.\n\nBegin with a warm base that provides both flavor and structure. A lightly seasoned protein, whether beef, poultry, or a plant-based alternative, offers heat and depth. Let the meat rest briefly after cooking so the juices redistribute, then fold in a modest amount of seasoning and a touch of water to finish the mixture. The goal is a filling that remains loose enough to scoop when warm, yet thick enough to stay put within the tortilla. Next comes a layer of melty cheese. A steady sprinkle of a mild, high-melting variety acts as a natural binder, inviting the other ingredients to cling rather than slip away. Cheese doesn’t merely embellish; it helps the burrito hold together during the roll and keeps the interior from drying out as it travels through kitchen prep and onto the plate. The cheese should melt into the hot filling, creating a seamless transition from center to edge.\n\nThe first true test of texture happens after the base is set: the introduction of crisp, fresh elements that contrast with the softness around them. Diced lettuce or shredded cabbage provides a refreshing snap, while pickled red onions offer a tangy bite that brightens the richness without overwhelming it. These components should be added in a way that their moisture is controlled—crispness stays intact when the burrito is sliced or bitten into, and the vegetables don’t release heavy moisture that soaks the tortilla. In tandem with crunch, creamy elements are essential. A generous dollop of guacamole or a spoonful of sour cream offers richness and a silky mouthfeel that tempers heat and rounds out flavors. If you reach for yogurt or a light crema, keep the portion measured and consider a tangier finish to prevent the dish from leaning too soft.\n\nBright, fresh salsa is the finishing touch that can lift the entire composition. Pico de gallo or a green salsa verde supplies acidity and herbaceous lift, which cleanses the palate and prevents the bite from becoming heavy. The salsa should be bright and not watery; if you’re making it at home, allow it to rest briefly so the flavors meld without releasing excess moisture into the burrito. A final drizzle can be applied at service, just enough to wake the flavors without turning the tortilla into a sponge. Moderation here is the subtle art; the burrito arrives on the plate with a perfume of brightness that invites the eater to keep coming back for another bite rather than beginning the unwinding of a soggy interior.\n\nSauces are powerful accents, but they must be used with restraint. A little chipotle crema, a touch of mole-inspired richness, or a garlic-forward aioli can elevate a burrito dramatically, but a generous hand with sauces risks turning the tortilla into a soggy conduit that defeats the purpose of careful layering. When space allows, pre-portion sauces into squeeze bottles or small cups, and offer them on the side where guests can control each bite. This approach mirrors how professional kitchens manage throughput in high-volume environments, ensuring consistency while allowing for personal preference. If you choose to incorporate a sauce directly into the filling, blend it with the meat so the flavor is evenly distributed rather than concentrated in one messy pocket.\n\nAn often overlooked but critical detail is the ordering of layers. You want a wheel of flavors that unfolds gently as you eat. Start with the warm base of rice and beans as a cushion; they create a soft, forgiving surface for the meat and cheese. Rice, in particular, acts as an insulator, keeping the tortilla from becoming too wet while providing a neutral flavor that supports stronger toppings. The beans serve a dual purpose: heft and moisture retention that helps the burrito maintain its shape during handling. The protein sits atop this foundation, followed by the cheese and the crisp, bright toppings. Finally, a modest amount of salsa and any creamy adjuncts should sit toward the top, where they can contribute moisture and zing without saturating the entire roll. If you’re preparing multiple burritos for a crowd, consider a build-and-assemble station where dry ingredients are portioned and warm, then the components are combined in a consistent sequence before final wrapping. The result is uniformity across dozens or hundreds of burritos while maintaining the integrity of texture and flavor in every bite.\n\nFor home cooks aiming to approximate the efficiency of a taco truck, the idea of a controlled, repeatable assembly process is invaluable. A practical approach is to organize ingredients by moisture and temperature, ensuring warm components help melt cheese and soften tortillas without dispersing excessive liquid into the filling. It can help to keep the tortillas warm but pliable—flicking a pan or a quick warm-up in a dry skillet for a few seconds can make a difference in how easily the burrito rolls and how tightly it holds together after wrapping. When rolling, think of the burrito as a compact cylinder that needs to stay closed. Fold in the sides first to tuck in the filling, then roll from the bottom with a steady action. A tight roll preserves structure and makes slicing cleaner, which is essential if you’re serving burritos to a crowd. Wrapping in foil not only keeps warmth but also helps the burrito retain its shape during transport, a small but critical detail if you’re recreating the on-site experience at home.\n\nA touch of technical discipline, borrowed from the professional world, can transform your home burrito into a road-ready product. The semi-automatic or mechanized approach used by busy kitchens emphasizes even heat distribution and consistent portioning. While not everyone has access to industrial machines, adopting the mindset—structured assembly, measured portions, and predictable heating—improves outcomes. If you ever mirror a professional method, a built-in step to rewarm the wrapped burrito gently just before serving can release aroma and soften the tortilla, letting the fillings mingle without turning the wrap soggy.\n\nFor those curious about connecting their burrito craft to broader operations, consider exploring sustainable practices in mobile food service as a companion read. It offers insights into maintaining quality at scale while respecting efficiency and environmental stewardship. Sustainable practices for mobile food trucks \n\nAs you refine your technique, you’ll notice how the balance between moisture, texture, and temperature shapes the eating experience. The key is to treat each burrito as a discrete product with a defined architecture: a warm, flavorful core; a binding layer of melted cheese; a crisp, fresh counterpoint; and a final kiss of brightness from salsa. The goal is a burrito that feels cohesive from the first bite to the last, its flavors layered in a way that invites a longer, more satisfying engagement with the food rather than a single, hurried mouthful. When this balance is achieved, a homemade burrito can stand shoulder-to-shoulder with the best taco truck renditions, offering the same sense of transportive flavor and comforting heft in every bite.\n\nThe practical upshot is uncomplicated: start with a solid base, layer thoughtfully, and season with restraint. Keep textures in mind, and let moisture and heat be your guides. If you’re cooking for a crowd, build in a station that mirrors the efficiency of a bustling kitchen, and use pre-portioned, stable components to maintain consistency. Reheating in a controlled way—wrapped and warmed just enough to melt the cheese and meld the flavors—will keep the burritos satisfying without surrendering their structure. And if you’re aiming for authenticity and scalability, embrace the concept of a build-and-bake workflow that ensures the tortilla remains pliable and the interior develops a harmonious, well-integrated flavor profile. The result is not merely a burrito but a portable, crave-worthy experience that travels well and tastes as vibrant as a night on the street corner.\n\nExternal resource for deeper technical grounding: Taco Machine Guide: Structure, Material Properties, and Performance Metrics. https://www.foodserviceequipment.com/taco-machine-guide

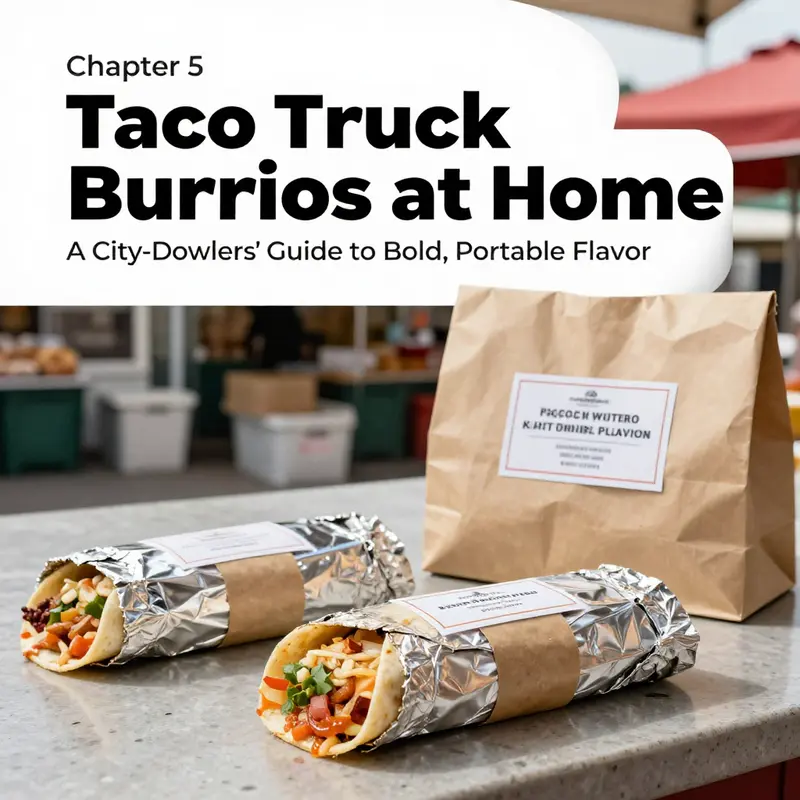

Chapter 5: Finishing, Packaging, and Authenticity: Crafting Taco Truck Burritos That Stay Hot, Travel Easy, and Speak Regional Flavor

Finishing a taco truck burrito is where the dream of street-style speed and home kitchen consistency converge. It’s the moment when every decision about filling balance, tortilla elasticity, and heat management pays off in a single, satisfying bite. This chapter threads finishing, packaging, and authenticity into one fluid practice, showing how precise technique and thoughtful presentation turn a simple tortilla and its fillings into a portable meal that remains vibrant from the steam table to the customer’s hands. The aim is not merely warmth or taste but a reliable experience: a burrito that holds its shape, resists sogginess, and tells a clear, honest flavor story that customers recognize as a real taco truck encounter, even when they’re eating in their own homes or on the go.\n\nFinishing begins long before the tortilla is touched by heat. It starts with tortilla prep, because pliability is the backbone of a sturdy roll. Warm tortillas to the point of bendable ease. On flour tortillas, a quick griddle touch on both sides enhances elasticity and aroma; for corn, a light toast can boost aroma without drying the surface. The goal is a surface that accepts a generous filling yet resists cracking or tearing during folding. Filling distribution follows a simple discipline: place the bulk of the ingredients along the center third of the tortilla, leaving ample margin at the edges for proper folding. Keep liquids in check—drain salsa or braises that tend to weep—so moisture remains within the filling rather than marching toward the tortilla’s interior.\n\nThe rolling technique is the visual and tactile hinge of the burrito. Fold the sides inward first, then roll tightly from bottom to top, using the tortilla’s natural seam to seal the structure. A light press or a parchment wrap can help set the seam as you finish, ensuring the burrito holds its form during service. A brief finishing heat, such as a quick sear on a hot plancha or grill for 20 to 40 seconds per side, creates a delicate crust that adds texture without drying the filling. If sauces or braises are involved, a thin glaze applied after the crust forms can heighten gloss and flavor, but be careful not to drench the surface and invite sogginess later on. Allow a short rest of one to two minutes, wrapped in clean cloth or parchment, to let the internal structure settle. Rest is not a luxury; it’s a practical step that helps the burrito hold together when wrapped for transport or placed into a hot-holding station.\n\nDifferent fillings demand slightly different finishing sensibilities, but balance remains universal. Carne asada and other grilled meats benefit from a proper sear that locks in juices without over-dripping moisture. Al pastor, with pineapple marinades, can tolerate a touch more moisture, but you should still drain excess juice to avoid a leaky end cap. Braised fillings—carnitas, barbacoa, cabeza, lengua—carry sauce and richness; counterbalance with a drier tortilla surface so the bite remains clean and focused. The mouthfeel should present a tug-of-war in a good way: a warm, pliable wrapper around savory filling, with a hint of crisp exterior that pops when the bite arrives. Fresh elements—onions, cilantro, lime—should retain brightness and crunch, not surrender to steam.\n\nPackaging is the second pillar of the burrito experience. The objective is to maintain heat and moisture in a way that preserves texture and prevents leaks, while presenting a neat, branded appearance. Primary wrapping options range from classic wax or parchment paper to aluminum foil and compostable liners. Paper wraps are reliable for heat retention and easy disposal; foil excels in heat retention and durability but can feel heavy and may trap too much moisture if overused. Compostable liners fit greener goals but must be compatible with local facilities. Secondary containment, such as cardboard burrito sleeves, trays, or shallow clamshells, reduces direct handling and helps maintain heat. An inner barrier—thin parchment or wax paper between burrito and outer wrap—can further limit moisture transfer.\n\nTemperature management is essential in any mobile setting. Store or display burritos at hot-holding temperatures, typically above 140–165°F (60–74°C), following local health codes. A two-stage strategy works well in busy contexts: wrap tightly for transport to the customer, then offer a quick refresh or open packaging at the point of sale to restore steam and aroma. Labeling should clearly indicate product name, preparation time, and major allergens as required by local regulations. If you offer multiple fillings, color-coded wrappers or small labels help staff and customers identify ingredients quickly, reducing delays and cross-contact risk.\n\nAllergen and dietary considerations deserve careful planning. Clearly segregate or label fillings that contain common allergens, such as dairy or gluten-containing sauces. For vegan or vegetarian options, ensure cross-contamination is minimized during assembly and clearly communicate the vegan status in your menu descriptions. Branding and sustainability should guide packaging choices. Select materials that align with your restaurant’s image while supporting heat retention and ease of use. Strive for packaging that is recyclable or compostable, and plan a waste-diversion strategy with staff to minimize environmental impact.\n\nOperationally, packaging efficiency is a practice as much as an art. Create a dedicated station with pre-prepared wraps, papers, and labels. Train staff to wrap burritos consistently, aiming for uniform filling amounts and consistent tightness. Consider pre-weighing portions to ensure size uniformity during peak hours, which in turn stabilizes service speed and customer satisfaction. A well-designed workflow matters nearly as much as the burrito’s interior. The assembly line should separate tortilla prep, filling, rolling, finishing heat, wrapping, and pickup. Minimize cross-traffic between raw ingredients and ready-to-eat items. Use color-coded containers and clearly labeled stations to reduce mistakes and speed up line flow. Sanitation remains non-negotiable: surfaces, boards, utensils, and wraps must be cleaned and sanitized between batches or at defined intervals.\n\nAuthenticity must be woven into finishing and packaging without compromising safety or practicality. Authenticity can signify traditional ingredients, regional techniques, and the historical context of burritos. Street-service authenticity, however, also hinges on speed, consistency, accessibility, and safety. Northern regions of Mexico often favor flour tortillas for burritos, and Sonoran-style burritos reflect a specific balance of rice, beans, meat, and potatoes in a large wrap. Corn tortillas connect more directly to many Mexican traditions, but their handling differs in a burrito format. If you want to foreground authenticity, offer a regional interpretation—such as a Sonoran-inspired burrito with a flour tortilla, carne asada, potatoes, and a distinct salsa—and label it clearly. Authentic storytelling can differentiate your truck, but it must be accurate and respectful. Share concise notes about techniques or ingredients that evoke a region’s character, such as nixtamalized corn or a particular chile blend, without turning your operation into a lecture.\n\nWorkflow and quality-control practices keep the thread intact from prep to plate. Critical control points include temperature management, moisture control, and cross-contamination prevention. Visual checks confirm uniform burritos with a light crust and evenly distributed fillings. Texturally, fillings should be tender but not mushy, tortillas pliable but not dry, and the exterior crust should invite the next bite. Flavor checks ensure salt, acidity, and heat balance remains consistent across batches. Troubleshooting should be proactive: soggy burritos signal excessive moisture or over-warming; dry burritos may benefit from a light rehydration on the tortilla surface or a fresh pico at service; tearing wraps points to inadequate warming or overfilling and calls for a tighter roll or a larger tortilla.\n\nA practical workflow example can anchor these principles during a busy shift. Pre-shift, pre-warm tortillas and prep fillings within safe holding limits, then portion toppings and sauces. During service, follow a disciplined sequence: warm tortilla, add filling, fold and roll, finish on heat for texture, rest briefly, wrap, and label. Move finished burritos to a hot-holding station or an insulated bag for service, and replenish components as needed. End-of-shift duties include inventory reassessment, proper storage to minimize waste, and a thorough clean-and-sanitize of the station. Document any quality notes to inform prep for the next day.\n\nTo consolidate the guidance, consider a concise quick-reference checklist: confirm tortillas are warmed to pliability; ensure even filling distribution with moisture kept in check; apply a light finish heat; allow a short rest; wrap securely with appropriate materials; maintain safe holding temperatures; label allergens; align packaging with brand and sustainability goals; verify regional authenticity interpretations and accurate menu storytelling; and maintain strict safety and sanitation practices.\n\nFor readers seeking deeper context or inspiration, a nod to sustainable practices in mobile food service can be useful. See sustainable practices for mobile food trucks for a broader lens on packaging choices, waste reduction, and operational ethics. sustainable practices for mobile food trucks\n\nIf you want a broader open-reference guide to truck-style burritos, an external resource offers in-depth perspectives on finishing and service. Learn more at the Taco Cart open guide: https://www.tacocart.com/taco-truck-burrito-recipe. This external reference complements the approach outlined here by expanding on heat retention, wrapping, and modular assembly that many operators use to scale up and maintain consistency across shifts.

Final thoughts

By embracing a structured, chapter-driven approach, you unlock the taco truck burrito experience in spaces as small as a home kitchen or a mobile pop-up. Start with dependable core fillings to create a solid flavor foundation, then master tortilla warmth and tight assembly for clean bites every time. Plan for batch cooking so you can serve more people without sacrificing quality, and layer toppings and sauces to deliver texture and brightness that stand up to busy service. Finally, finish with packaging and presentation that preserve heat, protect freshness, and convey an authentic street-food vibe. For urban commuters, outdoor enthusiasts, and small-business operators alike, this method translates a beloved street-food ritual into practical, repeatable steps—no special equipment required, just smart planning and a little showmanship.